Polypropylene pipes: the diameters for plumbing and heating

The continuous affirmation of plastic materials in the hydraulic world is an established and continuously developing fact. The absence of corrosion and resistance to chemical attack enable systems to function according to optimal design criteria, extending the life of the system. Aquatechnik was the first company in Italy to spread the benefits of PP-R, making its way into an industry culture rooted in use of metals.

Polypropylene pipe: PP-R, PP-RCT and PP-RCT WOR

Polypropylene is a versatile piping material used in a wide range of applications. Due to their high resistance to high temperatures and pressures, PP-R pipes (random copolymer polypropylene) and their evolution into PP-RCT (random copolymer polypropylene with modified crystallinity) are suitable for pressure systems, for the transport of drinking water but also other fluids.

PP-R, which was first used in Europe in the 1980s and introduced in North America in the 2000s, and its subsequent development into PP-RCT with increased pressure and temperature resistance, represent the alternative solution to more traditional metal systems thanks to the many advantages they offer.

The evolution of polypropylene pipe for Aquatechnik

The thirty years experience in the production of components for plumbing, mechanical and technological systems and the knowledge acquired, have allowed Aquatechnik to develop and customize specific products depending on the application for which they are intended. The most advanced base materials, exclusively from European production, are the PP-R 80 Super and PP-RCT, perfected by Aquatechnik with special additive mixtures, which are more resistant to the action of oxidants and metal ions, giving high stabilization at high temperatures: this is how PP-RCT WOR was born (increased resistance to oxidation). The modifications made to the raw material, not only improve the quality standards and technical performance of the material, but also fully respect the organoleptic and potability characteristics of water.

Advantages of polypropylene pipes

The use of PP-R and its evolutions as an alternative to metals offers several advantages to plumbers and designers of plumbing and industrial systems.

- Lightness is one of the main advantages offered by polypropylene pipes. Its density is 0.91 g/cm3, 80% less than steel pipes and 90% less than copper pipes. This leads to a significant reduction in transport costs and facilitates the installation process.

- Compliance with drinking water transportation regulations. PP-R pipes are safe and reliable due to the absence of chemicals harmful to human health.

- Polypropylene pipe does not rust or suffer electromechanical corrosion.

- The thermal conductivity at 20°C of PP-R is λ 0.220 W/mK, resulting in energy savings especially in heating systems.

- Minimal resistance to water flow, as the inner wall of the PP-R pipe has a roughness of only 0.007 mm, significantly less than that of metal pipe.

- High resistance to high temperatures and pressures. In particular, Faser FIBER pipes guarantee an increase in performance of 20% in use with cold water, and up to 50% for hot water compared to a single-layer pipe of the same thickness and conditions.

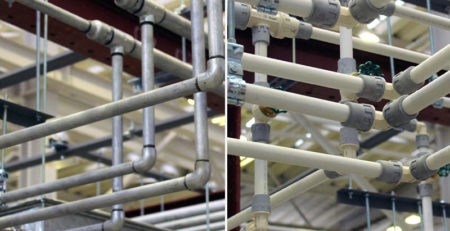

- Quick and safe installation. Joining by polyfusion is fast and safe.

- Wide diameter range. Pipe and fitting series covers a range of diameters between 25 mm and 630 mm.

Polypropylene pipes: the diameters available for every application

Material characteristics are crucial at the design stage in order to understand and predict the behavior and performance of the installed system: flow rate, temperatures, pressures, and material strength are all characteristics that affect the operating conditions of the system and its life expectancy.

An indispensable element in flow rate design is the calculation of pipe dimensions. In order to optimize the flow rate through a pipe network, efforts should be made to minimize pressure or head loss in the system. Pipe sizing must always be carried out according to the concept of cost balancing with efficiency and reliability.

PP-R pipes are available in various wall types and thicknesses (SDR 6, SDR 7.4, SDR 11, SDR 17.6) depending on the required pressure rating and operating temperature. Pipes with thicker walls have higher pressure ratings, while those with thinner walls have lower pressure ratings.

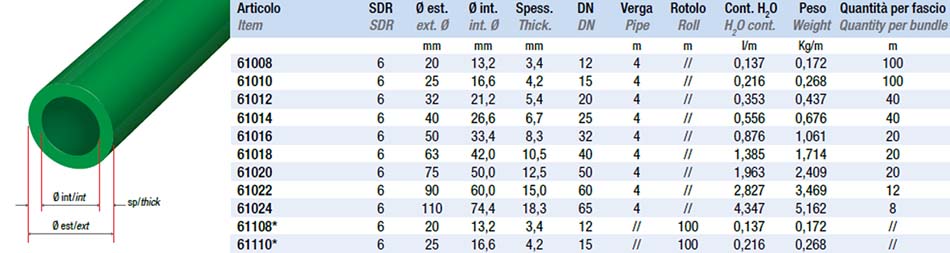

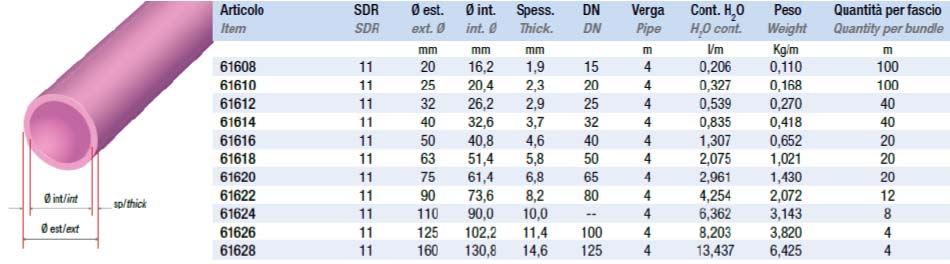

Fusio-technik SDR 6 single-layer

The single-layer PP-R 80 Super Fusio-technik SDR 6 pipe is a reference point for hot and cold fluid distribution. Suitable for plumbing, heating, irrigation and compressed air systems in civil, industrial and service sectors, it also has high resistance to aggressive fluids.

It is supplied from diameter 20 mm to 110 mm in 4 meter bars and in rolls of 20 mm and 25 mm upon request.

Below are all the product specifications and available diameters for Fusio-tecnik SDR 6 polypropylene pipe.

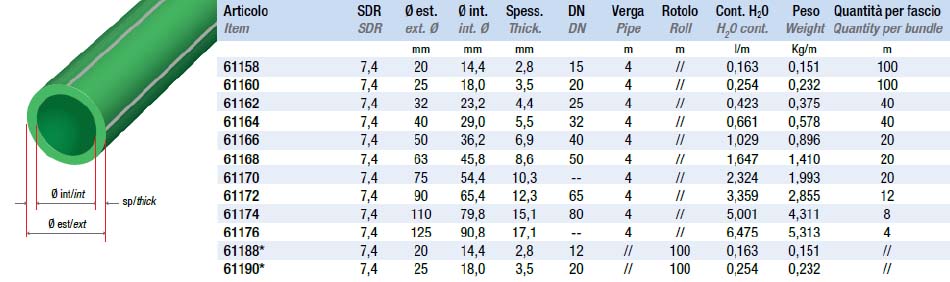

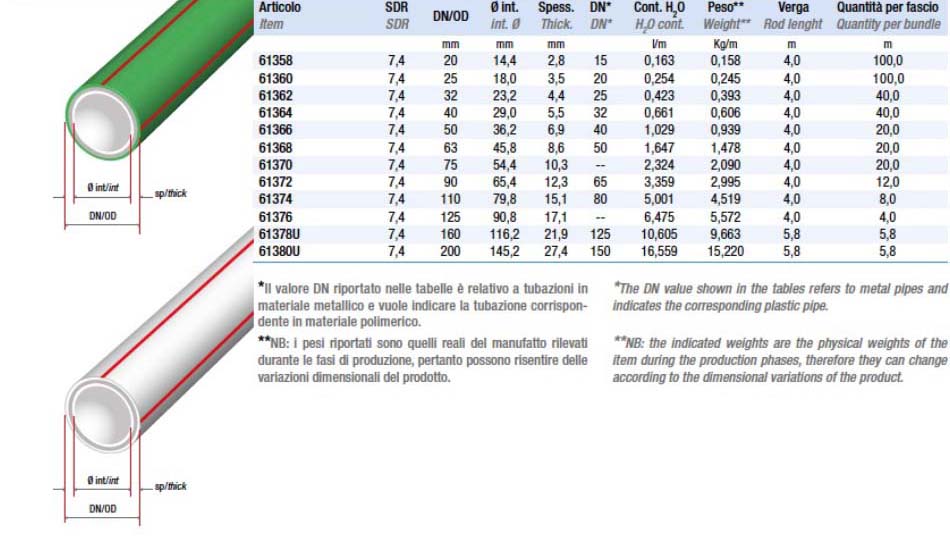

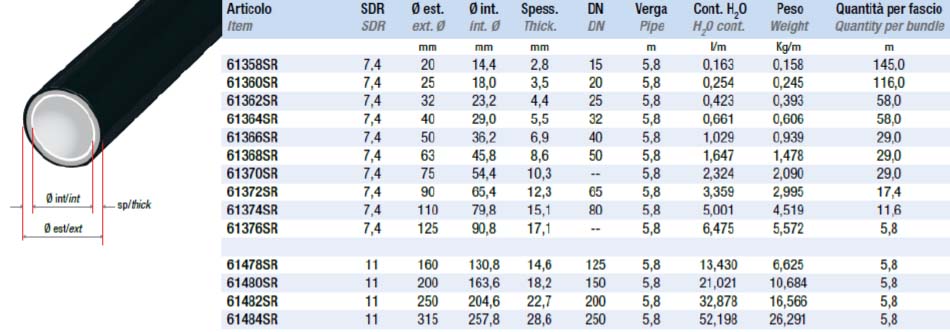

Fusio-technik Superflux SDR 7.4 single-layer

The 80 Super Fusio-technik Superflux SDR 7.4 polypropylene pipe is characterized by a reduced wall thickness, thus increasing the flow rate by about 20% compared to SDR 6 pipes. These pipes are particularly suitable for transporting aggressive fluids. However, we invite the installer to contact our Technical Department to assess the suitability of the system for transporting chemical fluids.

It is supplied in diameters from 20 mm to 125 mm in 4 meter bars and 20 mm and 25 mm in rolls upon request.

In the table all diameters and specifications.

Fusio-technik Rain-water SDR 11 single layer

The 80 Super Rain-water polypropylene pipe range was created with the aim of conveying recycled and reclaimed water. Additivated to increase resistance to alkaline acid PH, the pipe is distinguished by its violet color, as required by regulations. It is not suitable for conveying potable water and can be used in applications such as:

- Domestic use, such as toilets for power supply, toilet discharge boxes and power appliances

- Ornamental purposes, such as fountains

- Commercial uses, including vehicle washing, industrial process fluids

- Emergency water supply, such as feeding fire fighting tanks.

Available in diameters from 20 mm to 160 mm in 4 meter bars.

Details and all diameters follow.

Fusio-technik Faser FIBER-T SDR 7.4

Fusio-technik Faser FIBER-T multi-layer fiber-reinforced pipe can be used in a wide variety of application fields, from civil to industrial. The polypropylene pipe is suitable for heating, irrigation and compressed air systems. In details, the inner surface of the pipe is made of PP-RCT, which is random copolymer polypropylene with modified crystallinity and additives to increase its resistance to oxidation, while the middle layer is made of PP-RF, a fiber-reinforced copolymer polypropylene to reduce thermal expansion. Finally, the outer layer ensures ductility and strength with PP-R 80 Super.

Available from diameters 20 mm to 200 mm in 4 meter bars up to diameter 125, in 5,8 meter bars for larger diameters.

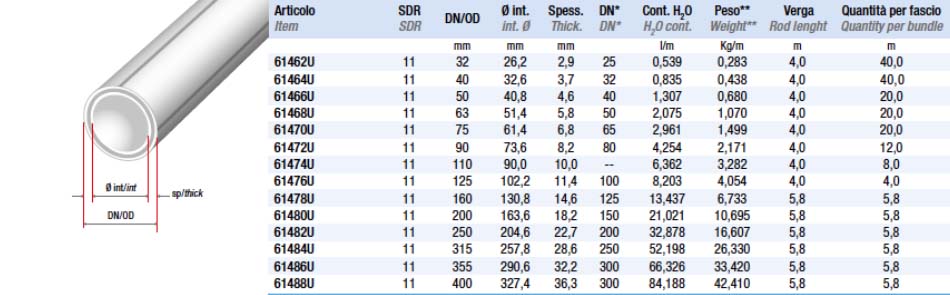

Fusio-technik Faser FIBER-COND SDR 11

Fusio-technik Faser FIBER-COND polypropylene pipes are characterized by high performance and lower thickness than conventional PP-R pipes, increasing water flow rate. Suitable for transporting potable water at medium temperatures and pressures, they are the product of choice for mechanical, heating and air-conditioning systems.

Supplied from diameter 32 mm to 400 mm in 4 meter bars up to diameter 125 mm and 5,8 meters for larger diameters.

In the table all available diameters.

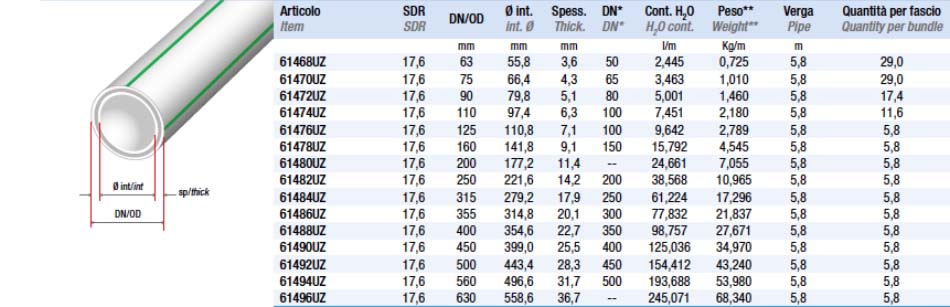

Fusio-technik Faser FIBER-LIGHT SDR 17.6

Polypropylene pipe for potable water distribution at low temperatures and pressures, suitable for mechanical, heating and air conditioning systems.

All pipes in faser’s fusio-technik line, in PP-RCT WOR, PP-RF and PP-R, comply with EN ISO 15874, DIN 8077-8078, ASTM F2389 and are the first fiber-reinforced PP-R pipes certified by IIP, ICC-ES and Lloyd’s Register.

Aquatechnik offers this piping from diameter 63 mm to 630 mm, in 5,8 meter bars.

In the table all the specifications for each available diameter.

Fusio-technik UVRES SDR 7.4 and SDR 11

The UVRES series pipes show a UV resistance increased by more than 30 times compared to normal polypropylene (15,000 hour test at UV irradiance of about 1200 KLy), making them particularly suitable for installations with direct solar exposure.

The SDT-R 7.4 version is available from diameter 20 mm to 125 mm in 5,8 meter bars, while the SDR 11 version, also in 5,8 meter bars, from diameter 160 mm to 315 mm.

Full details on technical specifications follow.

Polypropylene pipes in the sign of innovation

Ensuring the most efficient operation of water distribution, heating, and many other types of systems means choosing the best polypropylene pipe. Relying on a producer who makes quality his philosophy of continuous innovation is essential for always adequate responses to the market, indeed, to anticipate requests. Our experience in the plumbing industry, even overseas, leads us to exceed the expectations of installers and designers to always provide cutting-edge solutions. We invest in research and development for a more efficient and always environmentally friendly future, thanks to an integrated Quality and Environment management system, which has led us to significant certifications at both product and company levels, such as ISO 14001 and ISO 9001.