Practicality and advantages of the Safety-pol system with Multi-calor pipes compared to installations made of steel.

Safety means continuous innovation and surprising solutions.

The product, born with the objective of simplifying the installation and make the pipe-fittings joints safer, has confirmed its success with over 20 years of installations realised all over the world.

Sceptic-proof

It is 10.000 kms away that one of the most compelling and impacting test for our Safety system took place: the mockup project realised by Takasago Thermal Engineering Co., Ltd. In Japan, with the aim of making a comparative evaluation of functional and structural performances of the Safety-pol system with Multi-calor pipes, compared to installation made of steel. In order to have an objective environment, the installer used a single executive project: a ceiling structure with a size of 100 m2 in order to support 10 conditioning units. At the moment of installation, the company charged with installing had received a brief formation of about one hour on the working techniques of the Safety system, while it could boast a very big experience in the installation of metal plants. In the comparison project that took place in the Chiba prefecture, with diameters from 16 to 75 mm, the most glaring evaluations and advantages were related to the installation of the plant:

- it took seven and a half days to build the structure with pipes and fittings made of steel compared to only four with the Safety system. Working hours needed with Safety proved to be lower by 47%;

- considering pipes as well, the difference of weight between multi-calor and steel pipes greatly simplified the manoeuvrability and movements in the working site, therefore decreasing transportation costs;

- the processing (flaring) of Safety is standardized for all steps; therefore, the operators could learn easily the installation techniques and guarantee good quality in the construction process. The equipment, light and manoeuvrable, simplified working on site.

The Safety system and its advantages compared to installations made of steel

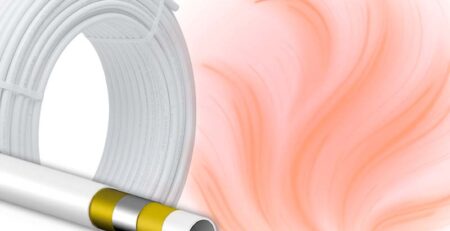

Safety is the product range that better represents the philosophy of quality and innovation that distinguishes us. Invented and patented by Aquatechnik, Safety is realised in polymeric material with great resistance to chemicals, temperature and stress that grant a life span of at least 50 years, a longer period of time compared to steel products. The system has two fundamental features: the widening of the external edges of the pipe (flaring) and the particular geometry of the fitting that allows the pipe to fit in an easy, fast and safe manner. The pipe is positioned and secured at the fitting using a cap that guarantees the mechanical seal while the O-ring the hydraulic seal. It is this joint technique that makes safety a total flow system.

Safety, protagonist of a practicality revolution

The extraordinary and surprising results of the comparison satisfied particularly the installer who recognised safety as an extremely simple, practical and safe system. This ambitious project managed, as a matter of fact, to highlight the multiple advantages that could be the starting point of a revolution in Japanese installations that, at this moment, has steel as the most commonly used material in the domestic market. The obvious advantages of the Safety system are a source of pride for all the Aquatechnik team. We thank Takasago Thermal Engineering Co., Ltd, leader in the installation sector in Japan for the realising this comparison. We thank our distributor Toyox Co. Ltd for suppling material and for immediately grasping and believing in the potential of our Safety system.