Aquatechnik for the Colnar winery in Slovenia

Aquatechnik’s fibre-reinforced pipes have reached Slovenia in an interesting project at a renowned winery.

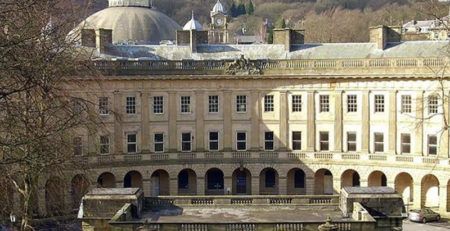

On the hills of Dolenska, lies 9 hectares of vineyards cultivated using biodynamic methods by the Colnar winery, born from a long and successful family history: a perfect combination of tradition and innovation, where different types of high-quality red, white, rosé and sparkling wine are produced.

It is precisely here that Aquatechnik systems can make the difference.

The aim of the project: high quality

In order to produce excellent products, every single step is important: temperature control is the key to the winemaking process, from when the must leaves the press to the fermentation, ageing and bottling stages. The wine is stored in stainless steel barrels, which must be maintained in stable environmental conditions, as the fermentation and storage temperature influences the activity of the enzymes that characterize the taste and olfactory properties of the wine produced.

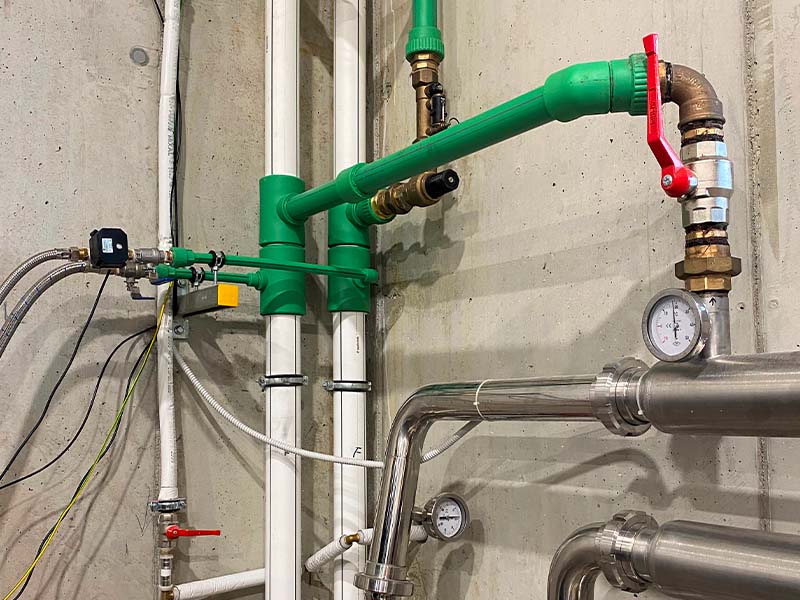

To achieve the desired result, a cooling distribution line containing a mixture of cold water and propylene glycol was created in order to regulate the temperature inside the stainless steel barrels and ensure optimal conditions for wine storage and ageing.

In line with the client’s philosophy and objective of quality, the equipment used to produce the best wine must also be top-class. Aquatechnik systems and, in particular, our faser FIBER-COND pipes with a diameter of 75 mm were therefore selected for this prestigious and modern facility.

The advantages of the faser FIBER range for cooling lines

Aquatechnik’s fiber-reinforced pipes were developed from the need to improve the resistance of an already high-performance material, PP-RCT, even further in order to guarantee even more long-lasting cooling, as well as heating, mechanical and compressed air systems. FIBER-COND, and all fiber-reinforced pipes, have a wall made of three layers:

- An inner layer made of PP-RCT, a random copolymer polypropylene with modified crystallinity and high chemical and long-term resistance. A state-of-the-art antioxidant additive package called WOR, White Oxidation Resistance, is added to this section.

- Central layer made of PP-RF, fiber-reinforced copolymer polypropylene, to reduce thermal expansion.

- Outer layer of PP-R 80 Super, for ductility and overall strength.

The PP-RCT combination with Aquatechnik’s WOR technology increases resistance to oxidizing agents by up to 40 times compared to PP-R monolayer, making the system more suitable for conveying added fluids and more resistant to sanitisation treatments. Their efficiency over time and the absence of corrosion make these pipes ideal for quality applications in any sector, with absolute compliance with the regulations governing the transport of drinking water. In addition, all pipes in the fusio-technik range have obtained the Declaration of Conformity for MOCA (Materials and Objects in Contact with Food), making them suitable for the food industry. Finally, the reduced weight compared to metallic materials makes installation easier and less costly.

Combining art and innovation with PP-RCT WOR fiber-reinforced pipes

Over the years, the winemaking business, based on the pillars of traditional craftsmanship, has benefited from the union with technological innovation. Raw materials that are skilfully worked and processed with state-of-the-art machinery: this is what made the meeting between Colnar and Aquatechnik possible in the project that saw the use of our faser FIBER-COND pipes. Available from diameters 32 to 400 mm, they are assembled by polyfusion, and were the first fiber-reinforced PP-R to receive IIP, ICC-ES and Lloyd’s Register certification.

We would like to thank the installing company Muhič for the excellent execution and our exclusive dealer for Slovenia Brown Bear Team d.o.o. for sharing this important reference.