Thermal power station with Aquatechnik manifolds and special pieces for the Sports Arena in Opera

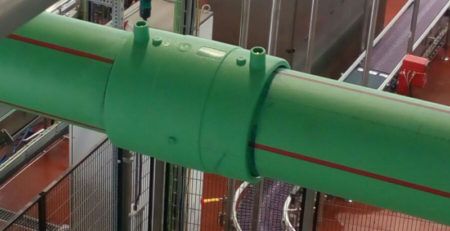

The thermal power station of the new Sports Arena in Opera is made with the faser FIBER-T and faser FIBER-COND pipes, equipped with relative fittings. The project is completed with manifolds and special pieces.

The new Sports Arena in Opera will be inaugurated during the year. The structure consists of several volumes, each characterized by its own function. The internal space has been designed to make each area autonomous and, after the approval of the Coni, the new building will have a “Silver” basketball court, which can accommodate professional basketball players. The main field, with space for about 500 spectators, will be able to host national volleyball and 5-a-side football matches and will be flanked by locker rooms and a nursing and anti-doping area. The secondary field, on the other hand, is approved for regional basketball, volleyball and 5-a-side football competitions.

An avant-garde space that will be a reference point for all sports fans, but not only. Aquatechnik contributed to the efficiency of the structure, created to meet the needs of modern urbanization, with the supply of manifolds and special pieces composed of fiber-reinforced PP-R pipes destined for the thermal power station.

The design choice of the thermal power station to optimize costs

Initially, some bureaucratic issues proved to be an obstacle for the project of the Sports Arena in Opera: these slowdowns made it necessary to proceed even more quickly as regards the construction of the thermal power station. The supply of manifolds and special pieces, based on customer specifications, has made it possible to meet the plant requirements, to optimize costs and to speed up processing. The ML-Engineering studio approved the variant with the Aquatechnik systems, while the company S.M.E.I.C. Impianti performed the installation with great professionalism.

Aquatechnik is able to manufacture manifolds on demand starting from the draft provided by the customer. From these indications we design the manifold, considering every hydraulic, dimensional, technical and material need, up to the final approval of the customer.

The advantages of manifolds and custom-made special pieces in polypropylene

The increase of specific demands of the market and the undisputed advantages of polypropylene in the plumbing and sanitary field have led Aquatechnik to create a production department equipped to produce manifolds and special pieces using the fusio-technik range. The pieces are assembled on specific requests of the customer, both in terms of geometries (dimensions, type and quantity of outlets, measurements), and in terms of the more technical aspect related to the choice of pipes and fittings. The Aquatechnik technical offices provide guidelines for the most correct selection of materials according to each specific use, to guarantee a product with the highest degree of performance at the best possible price.

Among the technical advantages of the system, we mention:

- greater safety of welding between pipes and fittings for quality and duration, which in fact leads to a single body. The guaranteed duration is 50 years and there are no corrosion phenomena;

- low pressure drops: fusions between fittings and pipe with total-flowing, low internal roughness 0.007mm;

- high mechanical stability and low linear expansion (fiber-reinforced PP-RCT, 0.035 mm / mK);

- greater cleaning. In metal products, sludge and residues released by the same material accumulate, compromising the operation of the system. This problem is absent in polymeric materials;

- energy saving, thanks to the reduction of thermal dispersion (0.19 W / mK);

- eco-sustainability, LCA cycle with low environmental impact, 100% recyclable.

In addition, the special PP-R manifolds also allow for easy installation, as they are lighter and easier to handle than those made of metal. Consequently, the handling and clamping phases are less expensive and faster.

Aquatechnik solutions for the best thermal systems

The construction of a thermal power station with manifolds and special polypropylene pieces offers the possibility of choosing from many different solutions and materials thanks to the wide choice of the fusio-technik range.

The study of the manifold that best suits your needs is the key to maximizing the efficiency of a project. The request can be forwarded to our sales network, indicating the maximum dimensions of the manifold and the number of outlets. Otherwise you can download the request form from the Utilities page of the download area of our site. The Aquatechnik technical department will provide a detailed technical drawing and a quote. Once approval is received, we will start the production of the manifold, which will be subjected to the most rigorous tests, usual procedure of our works.

Contact our sales network to get all the advantages of a tailor-made Aquatechnik solution.