The Brunswick School project: PP-RCT WOR piping wins over metal

Aquatechnik pre-insulated pipes were used for the heating system of a prestigious school in the United States.

Brunswick School was founded in 1902 by George B. Carmichael and is counted among the most exclusive private boys’ schools in Connecticut. It accommodates about 1,000 boys from Kindergarten through Upper Grade, in a functional, modern facility that yet tells of its historic value.

The heating system renovation project was handled by our partner Aquatechnik North America.

Polypropylene vs. metal pipes

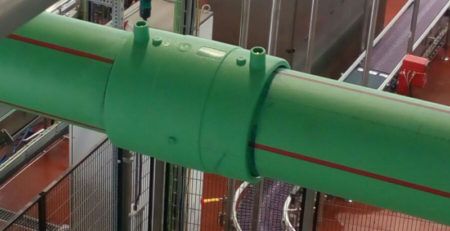

Metal piping systems have been the industry standard in the United States for generations and continue to be widely used for heating and cooling installations. However, a highly advantageous alternative to galvanized iron, steel, and copper has now made its way into the marketplace: polypropylene technology, which, together with PUR foam insulation and PE-HD coating, provides incomparable advantages in efficiency and energy savings. The evolution of PP-R is PP-RCT WOR, made by Aquatechnik for the production of fiber-reinforced pipes that were created inspired precisely by experience in the North American market, where water disinfection involves particularly aggressive chlorine-based treatments. In order to increase the effectiveness of the pipes in terms of durability, WOR (White Oxidation Resistance) technology was born, with the result of definitively overcoming the limits of metal pipes in terms of performance.

- PP-R pipes are more resistant to chemical attack than metal ones. Polypropylene is not object to corrosive phenomena. The obvious example was the project at Brunswick School where pre-existing insulated metal pipes, which had already degraded after only 15 years, were replaced.

- Thermofusion prevents leaks. In addition to corrosion causing leakage of the transported fluid, the weak point for metal pipes are joints, a problem that can be solved by using polypropylene pipes joined by thermal fusion. Metal pipes require welding processes with temperatures of over 1000°C, while polypropylene requires temperatures of about 200/250°C. Polypropylene also proves to be more advantageous than other polymeric materials (PVC for example) that require joining techniques using chemicals such as solvents/adhesives.

- Polypropylene piping is lighter and facilitates installation, which is also simplified by the light weight of the material, easier to transport, resulting in lower costs at the construction site.

- Higher flow rate and smoother inner surface. PP-RCT pipes have a non-porous surface, which does not offer resistance to the passage of fluid, reducing Pressure Losses and avoiding accumulation that can affect the proper functioning of the system. The higher flow rate and reduced friction benefit energy savings by allowing the pumps to operate at lower speeds.

The energy-saving advantage with iso-technik

An important advantage of polypropylene pipes over metal pipes is further emphasized with the pre-insulated version of Aquatechnik fiber-reinforced pipes: the low thermal conductivity λ of the service pipe. In fact, the thermal conductivity is significantly lower than that of metal pipes: for polypropylene service pipe 0.19 W/mk, compared, for example, to 22 W/mk of steel. This figure is further improved by insulation using stiff polyurethane foam (PUR), which has an initial λ of 0.0142 W/mK, while the aged thermal conductivity is 0.0235 W/mK. An advantage allows hot water, drinking water, and heating or cooling water to be transported over longer distances with reduced losses, providing real investments in energy savings.

The underground pre-insulated piping installed at the American school supplies a boiler with operating temperatures from 10 to 80°C and a pressure of 2 bar, conditions that can enhance the benefits of using faser iso FIBER-T, pre-insulated PUR pipe protected by PE casing and with faser FIBER-T service pipe (SDR 7.4), made of PP-RCT WOR with high resistance to high temperatures and oxidative processes.

Aquatechnik innovation for the best district heating systems

The traditional installation method for underground applications involving rigid metal piping systems (e.g., copper or steel) and then applying an external coating on site is expensive and impractical. Installation is time-consuming and complicated by making multiple welds, whereas iso-technik polypropylene preinsulated pipes provide significant time and cost savings while ensuring consistent performance and efficiency. Durability and material strength make them a better and more profitable choice in the long-term as well.

Plastics innovation in heating system manufacturing can make a difference!