Aquatechnik systems: excellence for heating power station in the Centroparco residential complex

In the ambitious undertaking to create an oasis of modern life on the outskirts of Milan, Aquatechnik systems are the protagonists of a quality project in the Centroparco residential complex in Segrate.

This green oasis, characterized by six buildings housing 500 units, is the testimony of the commitment to redefine urban life in unexpected places.

Nestled in the quiet outskirts of Milan, Centroparco represents a harmonious union of architectural style and nature. The complex is conceived as a sustainable community in which modernity is integrated with an eco-friendly philosophy. The aim of this project is to create residences that go beyond conventional living spaces, aspiring to be modern and comfortable homes in tune with the tranquility of their surroundings.

Aquatechnik’s innovative systems play a key role in creating the infrastructure that constitutes the backbone of Centroparco’s vision. Aquatechnik’s choice for sanitary distribution and underfloor heating and cooling systems reflects a commitment to cutting-edge solutions that prioritize efficiency, sustainability and durability.

Testimony of Andrea Valtolina, Marvel s.r.l. Managing Partner, about the project

From the 3D design to the construction site: plant optimization

In a project where modern means sustainability, heating power station and sanitary distribution systems are a technological base to ensure the efficiency of the whole complex.

The essence of innovative design lies in recognizing the dynamic interaction between cutting-edge technology, environmental sustainability and the unique needs of the Centroparco project.

Heating power stations, which are the lifeblood of the complex, must not only meet the immediate needs of the residents, but also align with the aim of creating a sustainable and ecologically sensitive living space.

For this reason, the Marvel company, which built the plants, has involved the DM Progetti studio: the beginning of this journey towards excellence starts with a meticulous 3D design phase, a milestone in the development of heating power station. Using the power of three-dimensional presentation, it was possible to imagine every component, pipe and junction, ensuring a complete understanding of the intricate network that feeds and regulates the housing complex.

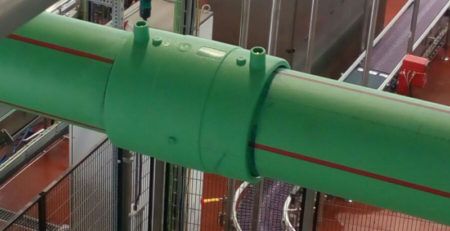

The 3D design not only facilitates a thorough examination of spatial dynamics, but also lays the foundation for a processing level that meets the highest standards. Visual representation helps to identify potential challenges, optimize space efficiency and refine the details of heating power station before the actual construction phase. This strategy, made possible by the accessibility of the BIM (Building Information Modeling) models of the Fusio-technik system, which can be downloaded from our website, marked a significant leap forward: “From the main part, to the distribution part, to the optimization of the final result and execution time”, as Andrea Valtolina, managing partner in Marvel s.r.l., tells us.

The advantages of Aquatechnik fibre-reinforced pipes for the Centroparco project

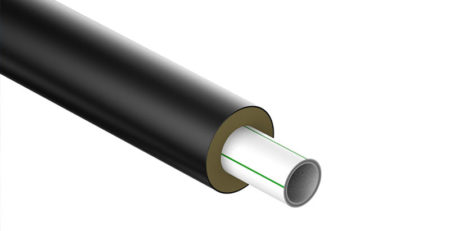

“We decided to use Faser FIBER-T and Faser FIBER-COND systems because we have known them for several years. The staff has learned to use this material, which has more advantages“, Valtolina confirms.

- Ease of installation. Marvel s.r.l. took advantage of the easy installation of the Fusio-technik system for a fast and efficient process. Thanks to the thermofusion (polyfusion) joints, interruptions are eliminated during the installation phase, reflecting the strategic synergy between technology and implementation.

- Corrosion resistance, a fundamental pillar of Aquatechnik systems. In the context of Centroparco, this feature ensures the longevity of the installed infrastructure, resisting corrosive forces that can compromise the integrity of the system over time. This feature not only safeguards against potential malfunctions, but also strengthens the sustainability of the entire network.

- Electrochemical resistance. The material from which the fibre-reinforced multilayer pipes are made, PP-RCT (random copolymer polypropylene), PP-RF (fibre-reinforced copolymer polypropylene) and PP-R 80 Super, is resistant to any corrosion phenomena and therefore is not affected by stray currents in the soil which can cause deterioration of sensitive materials (metals).

A complete range: Faser FIBER-T and FIBER-COND

Among the strengths of the system chosen for the project is the wide availability of diameters: “It has a complete range from the smallest to the largest diameter, to use a single material at both pipe and fitting level”, as the owner of Marvel s.r.l. explains.

The strategic choice of Aquatechnik systems allows the use of a single material for the pipes and fittings of all installations. This decision goes beyond mere convenience; it becomes a key element in streamlining logistics and promoting a sense of simple cohesion within the project. Using the same system simplifies the supply process and also establishes a strong synergy between the components, contributing to the overall efficiency and reliability of the distribution network.

Fusio-technik Faser FIBER-T SDR 7.4, with PP-RCT WOR (White Oxidation Resistance) inner layer, is available from diameter 20 to 200 mm, in 4 m bars up to diameter 125 and 5.8 m for larger diameters.

Fusio-technik Faser FIBER-COND SDR 11 pipes are available from diameter 32 to 400 mm, in 4 m bars up to diameter 125 mm and 5.8 m bars for larger diameters.

The articles used are also non-toxic, and therefore suitable for drinking water transport, and 100% recyclable, as well as having an environmentally friendly LCA cycle.

Professionalism at the service of innovation

Every step of this collaboration, from the innovative 3D design to the use of Aquatechnik’s state-of-the-art systems, converges towards the creation of a residential environment that is not only sustainable and modern, but is also a testament to the potential of collaboration and technology in redefining the boundaries of plumbing design.

The success of this project lies not only in the technical skill demonstrated, but also in the perfect partnership that has developed with Marvel: “I would like to thank Aquatechnik for the technical support they have given us, for their professionalism and, above all, for their willingness to provide the material at the right time and to be supported by a serious company”, Andrea Valtolina tells us with satisfaction.

In this spirit of excellence, we celebrate a new triumph, looking forward to new collaborations that exceed expectations.