Sustainability and efficiency: Aquatechnik pipes for the recovery of technical industrial water

We live the paradox of living the Blue Planet, so called because of the undisputed abundance of water, and of being increasingly concerned about the decreasing accessibility of this vital resource. In recent years, we have witnessed a growing consumption of water at both industrial and personal level, accompanied by irrational wastage, especially in relation to the recent climate variations that presage difficult water scenarios. In terms of personal consumption alone, it is estimated in our country that 215 litres per person per day is used, a very high figure that could be considerably reduced with simple measures. Moreover, more than 40% of water is literally wasted due to the inefficiency of the Italian water network. If in addition to these data, water consumption at industrial level and the recent drought-related water crises are taken into account, the situation certainly needs more than one consideration.

Each industry differs in its water consumption behaviour: some sectors use unjustifiably large volumes of water compared to others. According to the World Bank, the demand for water for industry and energy is estimated to increase to 228 billion cubic metres in 2025. In 1999, the demand was 67 billion cubic metres. The scope for reducing water consumption starts with a more targeted use, but also the recovery of water, not only rainwater, but also technical water.

Aquatechnik pipes for industrial technical water recovery

Among the uses of Aquatechnik’s polypropylene pipes, of particular interest is the construction of a plant for the recovery and reuse of technical water from industrial processes with connection of the self-priming lifting pumps to the purification station. The project carried out by Teknoimpianti of Pesaro, with the Filippo Aguzzi‘s Technical Studio of Plant Engineering, also included the creation of pressurised distribution lines to the users.

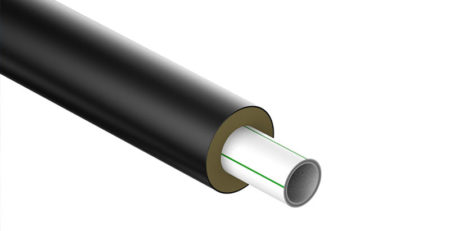

Colour-coded polypropylene pipes were used, as required by regulations. In fact, UNI 5634 states that pipes with a recovery function must be easily distinguishable from those carrying drinking water. For this reason, fusio-technik rain-water pipes, intended for wastewater recovery and reuse, have the classic violet colour used to transport recycling fluids.

The benefits of industrial water recycling

Industrial water reuse is the process by which wastewater produced from a certain source is treated to be reused in the same process or fed into another. Recycled water is in fact treated to remove contaminants and be used for irrigation, agriculture or industry and, with further purification, also for human consumption, becoming potable. The benefits of this process are diverse and include:

- Environmental protection and safety. Industrial wastewater often contains large quantities of pollutants such as heavy metals and petrochemicals. Indiscriminate discharge into seas and oceans affects the marine ecosystem and improper use reduces the availability of water for aquatic fauna and flora. In addition, recycled water can contain higher levels of nutrients than drinking water, thus reducing the use of chemical fertilisers for irrigation, for example. This also benefits health and safety, as controlling the quality of water released into the environment can certainly have a significant impact on all living organisms.

- Reducing costs. Various industries consume a lot of water for the production of their products, as well as for the most common uses. Just think of paper production or food processing, which require maintenance and water purification costs to use water in the production process. Water requirements are reduced by up to 90% by treating wastewater and reusing it. Energy is also saved by replacing collection and supply and bringing the source closer: recycling water on site or nearby reduces the energy required to move the fluid over longer distances or to pump water from the depth of an aquifer, which also has an effect on costs.

The benefits of polypropylene for water recovery: a sustainable approach

All the benefits of industrial water recycling would be in vain, however, if the best quality pipes were not used in the construction of the recovery plants, amplifying the efficiency and sustainability benefits.

Pipes releasing chemicals, easily susceptible to corrosion, have a significant impact on the environment and, more directly, on people’s health, not to mention reduced energy efficiency. On the other hand, water leaks and poorly resistant materials contribute to increased wastage and water contamination. The material that makes up rain-water pipes is polypropylene with a special mixture that increases resistance to low and high pH. These pipes have a high resistance to oxidation, pressure, corrosion and chemicals. As with all PP-R pipes, the joints between pipes and fittings are made by polyfusion welding. Another advantage of polypropylene is that it is a 100% recyclable material and that the production processes using it for the manufacture of pipes and fittings are low impact, meeting the basic requirements of an integrated quality and environment management system that complies with ISO 14001.

All in all, the combination of polypropylene and industrial water recovery facilities provides a truly eco-friendly solution that maximises the recycling objective for wide-ranging benefits.