Aquatechnik pre-insulated systems for industry

The iso-technik piping systems are used in various fields, thanks to the distinctive characteristics that guarantee their performance for any type of system. Iso-technik pipes are suitable for sanitary, heating and air conditioning systems, technical systems, cogeneration systems and in all those situations where the transport of thermal energy at a distance is necessary.

The out-of-excavation installation project for a Vicenza company

The air conditioning and connection lines to the heat pump have been made with pipes of the iso FIBER-COND series, which guarantee very low heat dispersion, both thanks to the composition of the service pipe and to its coating, elements that determine a more considerably heat conservation than metal pipes.

The structure of the building needed an aerial installation outside the excavation, a further reason for choosing pipes in polymeric material, whose lightness has favored greater maneuverability at the work site. In fact, consider that a steel bar of Ø 125 mm (length of 5.8 meters) has a weight of 104 kg against the 63 kg of an Iso Fiber-Cond bar of the same length and diameter.

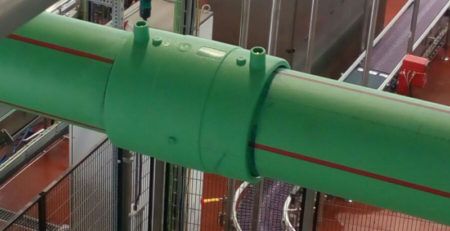

Again FIBER-COND, but in the bare version, for the construction of the thermal power plant in which custom-made collectors were also used in order to meet the specific needs of the structure and optimize the efficiency of the system.

The materials for the construction of the thermal power plant and the air conditioning lines were provided by our distributor Commerciale 98, whom we sincerely thank. The flawless execution of the project is thanks to Giulio Gatto and Mattia Grolla.

Aquatechnik’s iso-technik system

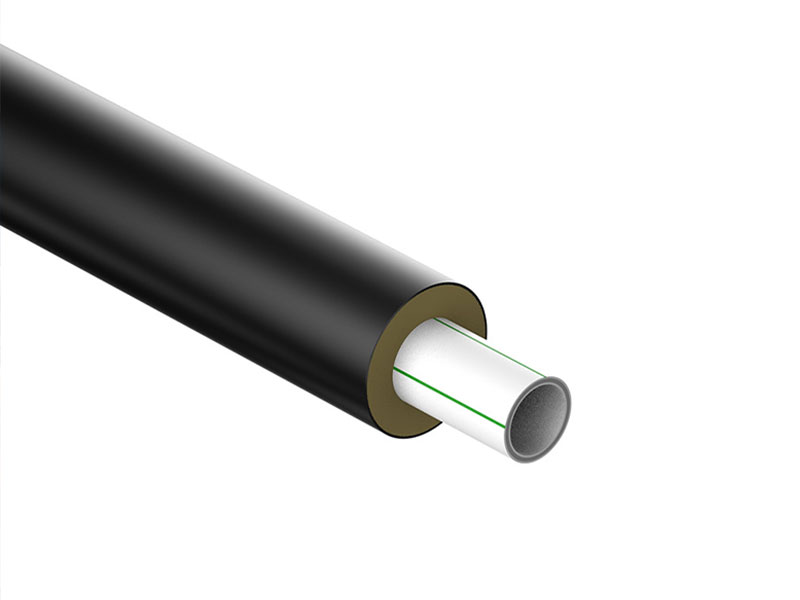

Iso-technik is a system of pre-insulated pipes and fittings in rigid polyurethane foam (PUR) protected by a black PE-HD containment sheath. The black color is indicative of the presence of carbon black, an additive present in a percentage between 2 and 3% which guarantees resistance to atmospheric agents, in particular to UV rays. The internal service pipes are composed of fiber-reinforced pipes of the fusio-technik series, made using the most advanced basic materials, including PP-RCT with WOR (White Oxidation Resistance) technology.

Thanks to the reduced heat losses, it’s the ideal system for the remote transport of energy through water carrier fluid. This advantage is the result of the low thermal conductivity of the service pipes (λ = 0.19 W / mK vs 52 W / mK of steel) combined with the characteristics of the PUR insulation.

Polyurethane foam derives from the combination of two elements, which are separately stable, while together they generate a chemical reaction that creates the foam: the content of closed cells, higher than 90%, implies the presence of air, a decisive element for thermal insulation. The values of the thermal conductivity foam, already very low compared to standards, have been further improved recently: Aquatechnik has managed to obtain an initial λ value of 0.0142 W / mK, significantly reducing the previous value, by 0, 0227. The stabilized thermal conductivity, used for the design, is now 0.023 W / mK, against the previous 0.027.

These advantages make iso-technik the ideal system for the remote energy transport between thermal power plants, chillers, heat pumps, geothermal systems, thermal systems and users that provide pre-insulated underground piping networks, guaranteeing maximum safety and design-application reliability.

Energy saving with Aquatechnik pre-insulated pipes

The strengths of fiber-reinforced pipes meet the additional advantages deriving from the insulation of the iso-technik system.

The low thermal conductivity and the characteristics of the system are suitable to the most varied applications, even more in systems where waste must be reduced, such as when it is necessary to convey energy from a heat production plant distant from the users. For example, in systems with heat pumps and high-performance machines, which have the increasingly pursued goal of saving energy and optimizing efficiency to reduce consumption, also benefit the environment.

The reduced energy loss, already deriving from the service pipe, is even more contained with iso-technik, with a consequent improvement in the efficiency of the system. For example, with 100 meter of ISO FIBER-T pipe, and the flow of water at 80 ° C at 1 meter per second, only 2 KWh are lost. With the same diameter, with FIBER-T, without insulation, the loss is 12 KWh, instead of 20 KWh with steel pipes.

Also the reduced pressure drops, thanks to the roughness of the pipes which generates low friction and favors the flow of the fluid, also reducing the necessary effort of the pumps that will work slower, consuming less energy, contributes to the optimization of consumption and make possible a more efficient operation of the system.

Other advantages of iso-technik

The other advantages of the iso-technik system include the ease of installation, thanks to an extensive range of pipes and numerous fittings, which have the same insulating characteristics as pipes. The joints are made by cup welding, with a diameter of 32 to 125 mm, butt welding from 160 to 315 mm, and electro-welding, with dedicated heat-sealing equipment, which makes installation faster and safer. It is also not necessary to use crane hoists or other equipment for handling during welding, thanks to the reduced mass weight compared to metal pipes, therefore with greater maneuverability of the materials.

The iso FIBER-COND range extends from diameter 32 to 315 mm. The service pipe is white with gray stripes, covered with PUR insulation and black outer casing. Suitable for the transport of cold and medium temperature drinking water (max 50 ° C).