Multilayer pipes: all available diameters

The multilayer pipe represents a versatile solution for applications in the most varied sectors and it is ideal to realise heating systems, included that with radiant panel and water conveying, warm and cold.

Widely used, among its main advantages there are resistance to high temperatures and flexibility of the pipe. For a correct installation that optimises the advantages of the multilayer pipe it is important, among the various available types, to choose the right diameter considering the intended application.

The typologies of multilayer pipes

The normative UNI EN ISO 21003-1:2009 distinguishes the typologies of multilayer pipes in “M” and “P”. The Multilayer M-pipe are different from P-pipes due to the presence of metal, and they are made of five overlapping layers. In multi-calor pipes by Aquatechnik, the internal and external layers are made of polymeric material, crosslinked PE-X.

The utilised materials contribute to make the multilayer pipes an advantageous solution. In particular, the polymeric layers grant non-toxicity and suitability to convey potable water, lightness of the pipe for easier handling, resistance to corrosion and reduction of pressure drops, thanks to its low roughness. The aluminium layer grants impermeability to oxygen and flexibility in installation, other than mechanical resistance and a reduced thermal dilatation.

Uses and classes: the diameters of multilayer pipes by Aquatechnik

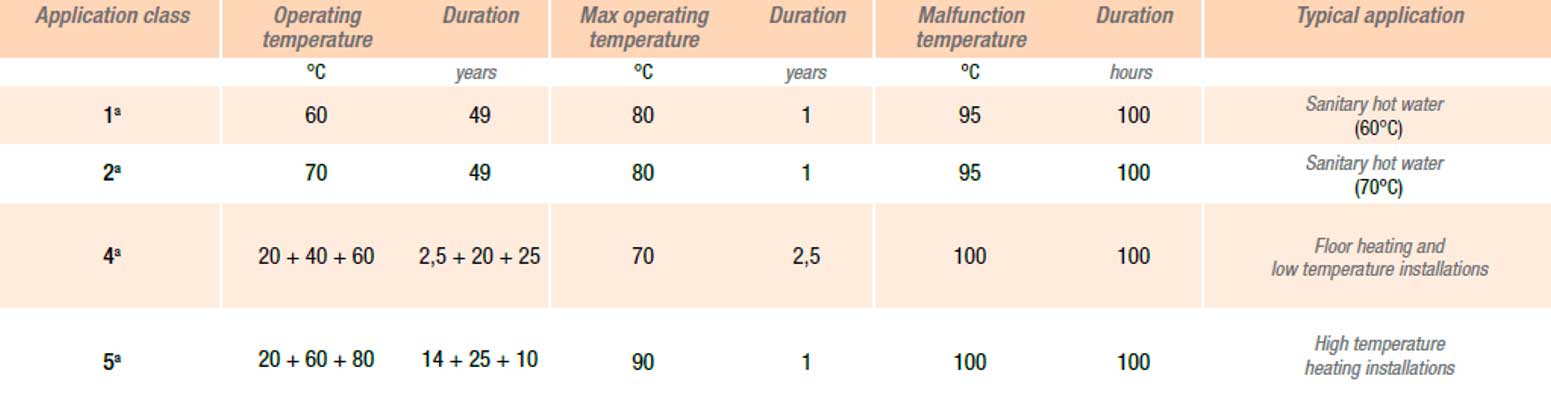

The international norm UNI EN ISO 21003 sorts multilayer pipes into four different classes:

- Class 1 for warm sanitary water distribution systems with maximum temperatures 60°C;

- Class 2 for warm sanitary water distribution systems with maximum temperatures 70°C;

- Class 4 for radiant heating systems and low temperatures systems;

- Class 5 for high temperatures heating systems.

In choosing the right pipe is therefore necessary to start from the conformity with these classes relative to the type of system that is going to be realised and subsequently to consider other factors, among them the maximum speed of the conveyed fluid, the flow and pressure drops.

The versatility of multi-calor by Aquatechnik

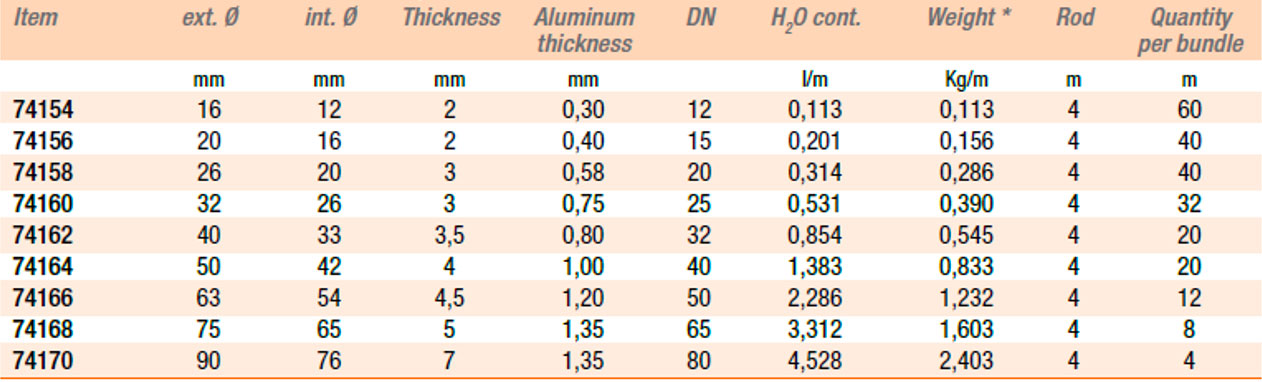

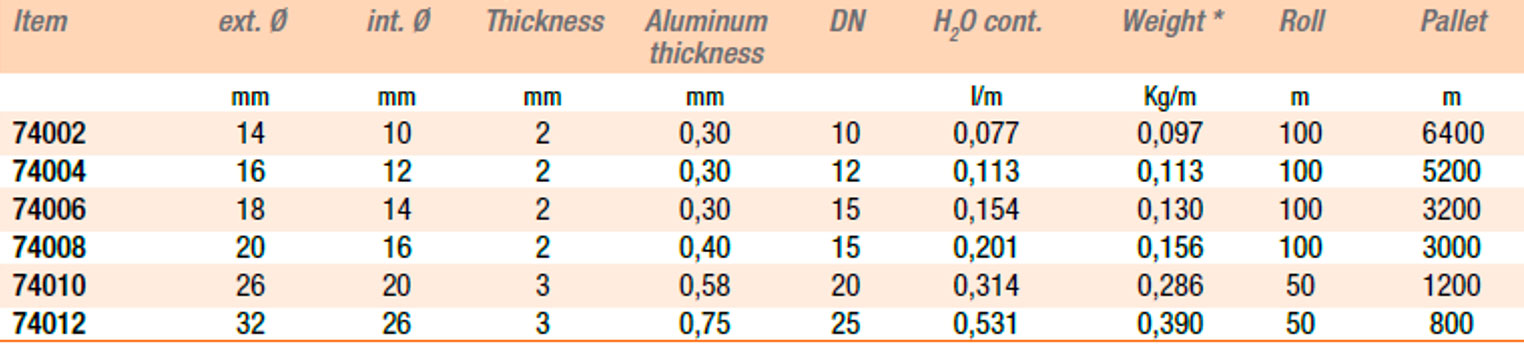

The multilayer multi-calor pipe is realised in PE-X/Al/PE-X. The cross-linking of the internal and external layers PE-Xb is made with silanes with a cross-linking value of at least 65%. In compliance with UNI EN ISO 15875-2, such pipes are suitable to realise hydrosanitary, heating and cooling, industrial systems to convey various liquids, compressed air, inert gases, potable and non-potable water, multi-calor pipes can be used in the most varied sectors, from civil to industrial and tertiary. They have a maximum working temperature of 70°C with peaks of 95°C, and minimum of -45°C. They can withstand a maximum pressure of 10 bar at 70°C and 25 bar (SF1 / 50 years) at 20°C. As briefly said before, multilayer pipes by Aquatechnik have a low roughness (0,007 mm) and a reduced coefficient of linear thermal expansion, with features similar to those of metal pipes, with α equal to mm/mK=0,026. Thermal conductivity, inferior to that of copper by about 900 times, varies between 0,42 ÷ 0,52 W/mK comparing to the diameter. Exactly the wide range of diameters contributes to make multi-calor the best among multilayers:

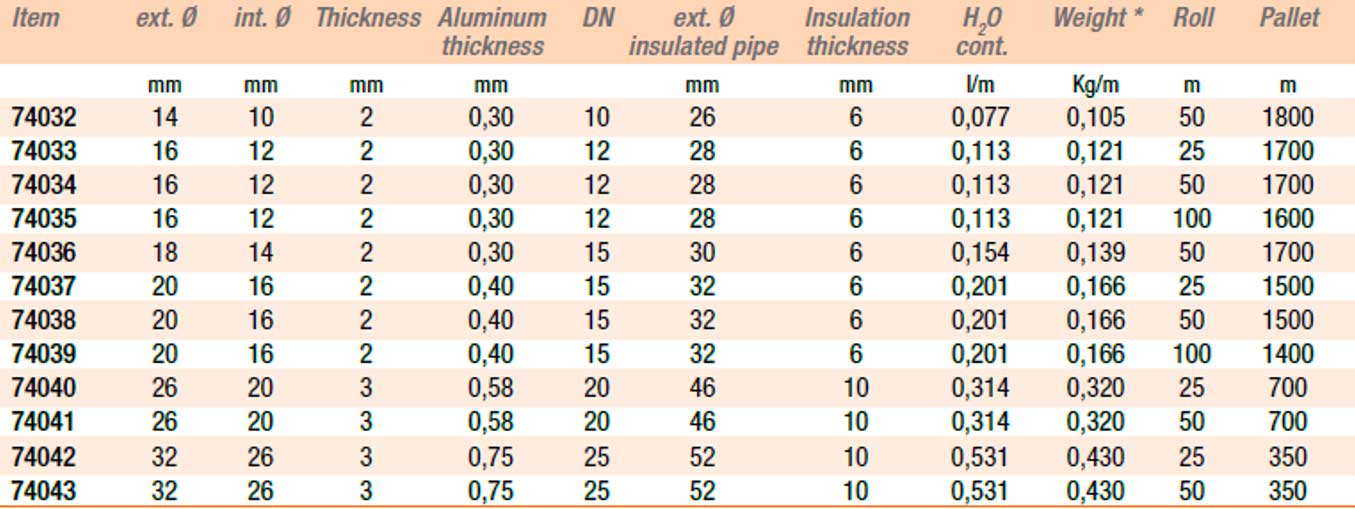

- Between diameters 14 and 90 mm, in rods 4 m long;

- Between diameters 14 to 32 mm, in rolls.

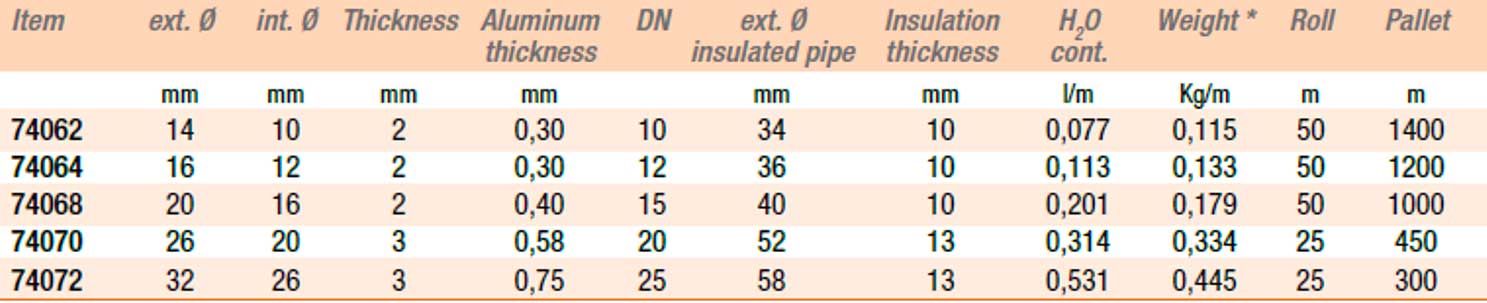

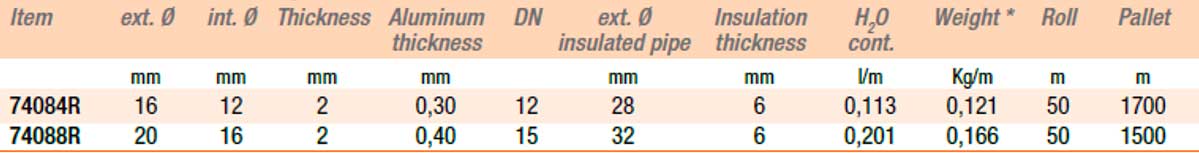

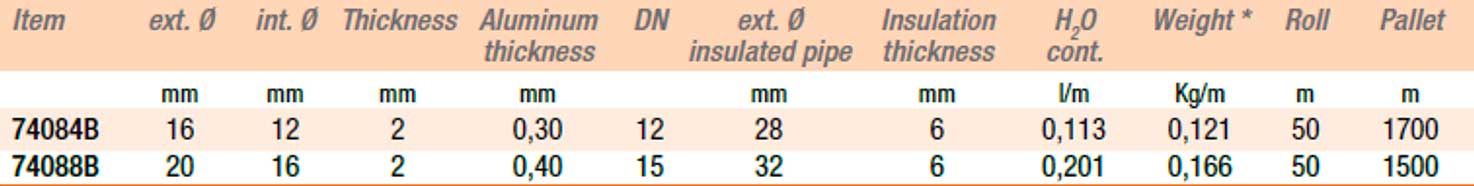

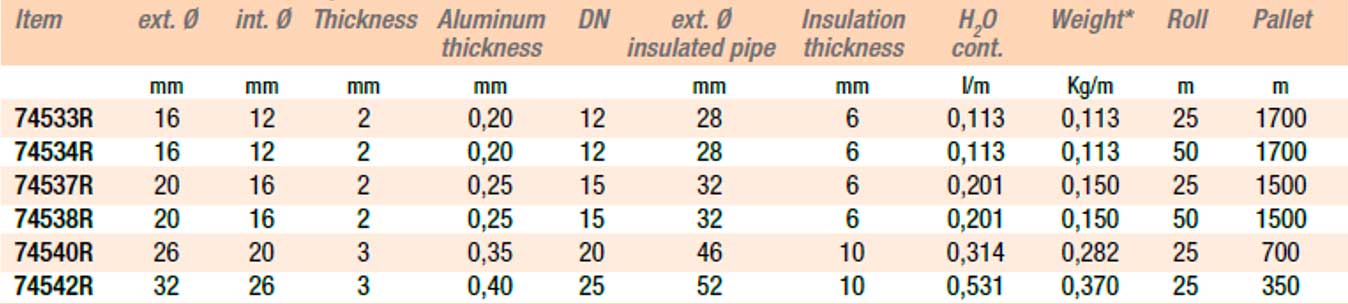

Pipe rolls in diameters from 14 to 32 mm are available also in pre insulated version, with coating made of closed cells polyethylene foam with a resistance factor to the spread of steam μ of around 5000 and thermal conductivity equal to λ =0,040 W/mK. The pipe is provided with polypropylene sheath in two colours:

- multi-calor pipe in rolls, with green thermo-insulating coating, for hydro sanitary systems at high temperatures (energy saving);

- Multi-calor pipes in rolls, with light-blue thermo-insulating coating, for heating, cooling and hydro sanitary systems (energy saving and anticondensation).

The multi-calor range with thermo-insulating sheath inclused isoline-plus as well, with themal conductivity of λ =0,035 W/mK:

- Multi-calor pipes in rolls, with red thermo-insulating coating, for heating systems at high temperatures with heightened insulating value.

- Multi-calor pipes in rolls, with blue thermo-insulating coating, for heating and hydro sanitary systems at high temperature with heightened insulating value.

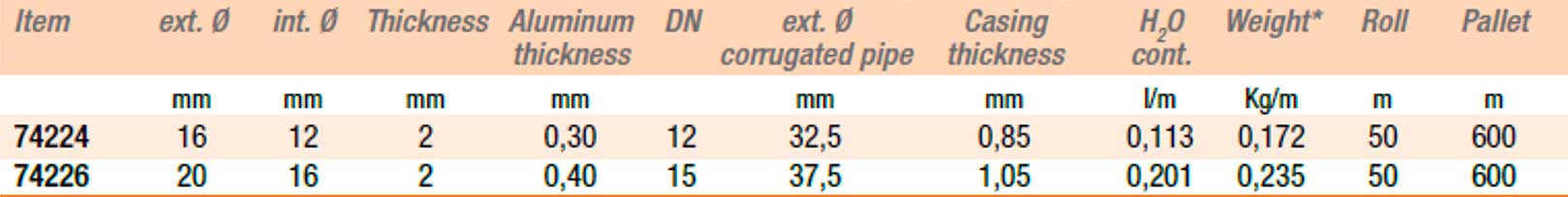

The range is completed with coated multi-calor pipes with blue or red corrugated casing for hydrosanitary distribution systems which require a certain protection or the possibility of removing and substituting the pipe:

According to aforementioned norm UNI EN ISO 21003 multilayer multi-calor pipes are certificated for all clases of application for pressures up to 10 bar.

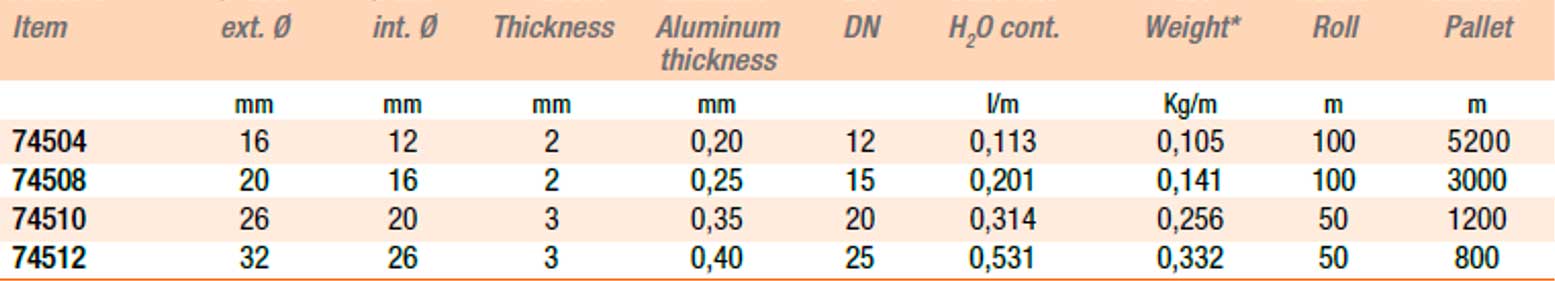

The convenience of multi-eco by Aquatechnik

The multi-eco pipes brings together high performance with advantageous prices. Realised in PE-X/AI/PE-HD, the multilayer multi-eco is different from multi-calor for the thinner aluminium layer and the external layer, in high intensity polyethylene instead of crosslinked polyethylene. Particularly the PE-HD grants greater flexibility, making multi-eco particularly fit to realise radiant floor heating and cooling systems. They offer nonetheless great performances for warm and cold potable water distribution systems, for radiator heating systems and convectors in civilian and industrial plants. The maximum working temperature for these multilayer pipes is 95°C, with peaks of 100°C, while the minimum is -45°C. The maximum pressure appliable is 10 bar at 70°C and 21 bar at 20°C. Same values of multi-calor for internal roughness, 0,07mm, and the coefficient of thermal linear expansion, α equal to mm/mK 0,026. Further reduced the thermal conductivity, still according to diameter, by W/mK 0,420 ÷ 0,440.

Multi-eco is available in rolls with diameters from 16 to 32 mm (Ø 18 mm excluded).

Multi-eco is also available in a version with thermoinsulating coating, covered with polyethilene foam, blue or red, amd thermal conductivity equal to λ =0,040 W/mK, specific for heating, cooling and hydro sanitary systems for energy saving and anticondensation.

Multi-eco pipes are also suitable for all four classes of application classified by UNI EN ISO 21003.

Multilayer polipert

The multilayer polipert pipes are realised in non-crosslinked PE-RT, feature that makes them particularly cheap and with a intermediate layer made of EVOH, ethylene/vinyl alcohol. The layers are kept together by an adhesive. Exceptionally flexible, polipert is ideal for radiant panels systems. It can be used with maximum continuous working temperatures up to 70°C and minimum of -45°C. The maximum possible pressure is 6 bar at 70°C. Internal roughness is the same as multi-eco and multi-calor, of 0,07 mm, while the values of linear thermal expansion and thermal conductivity are mm/mK 0,180 e W/mK 0,40 respectively.

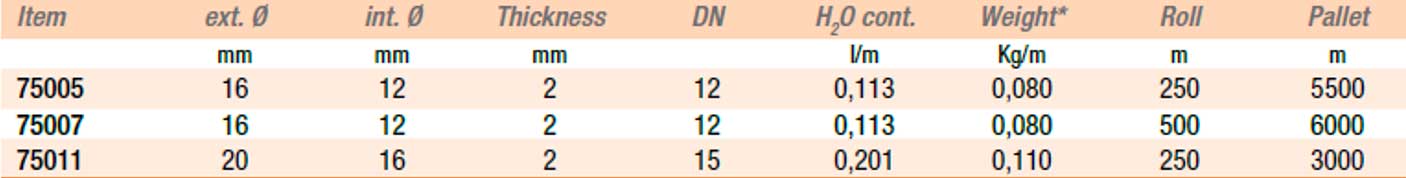

Polipert is available with diameters 16 and 20 mm, in rolls.

In comformity with ISO 22391 norm, the polipert pipe series can be employed in relation with the fourth class of application.

Designing systems with multilayer pipes by Aquatechnik

Our mission is to develop innovative products to simplify installations and applications and to improve safety and performance, which contribute to energy saving as well. We know that having the right materials and tools is fundamental to realise state of art hydrothermal sanitary systems. For this reason, we continue to innovate and improve our products, in a context of constant collaboration with designers and installers, granting a wide range of solutions that can satisfy any request. This quality ethics includes a global vision of a “system”, because it does not exist a pipe without fitting; the choice of fitting system must, indeed, contribute to highlight the pipes quality, like safety, the multilayer fitting system with total flow that grants simplicity and safety during installation. Aquatechnik is not only a technology for water, but also Italian design and excellence at service of who is searching for innovative solutions.