The suitability and safety of polypropylene pipes for drinking water

Polypropylene pipes have the most varied uses: the main advantage is their lightness, which facilitates transport and installation. Aquatechnik polypropylene piping systems are supplied with fittings and complementary accessories available for each pipe diameter. Now used all over the world, they are the best choice when it comes to drinking water piping systems.

The advantages of using polypropylene pipes for plumbing

Compared to other types of materials, polypropylene pipes have a very smooth internal wall, which greatly reduces friction and, consequently, reduces the pressure drop during fluid distribution. Unlike metal pipes, PP-R pipes are not subjected to corrosion, therefore they do not release residues that can clog the passage section. Polypropylene piping systems are adaptable and suitable for civil and industrial applications, including hospitals and hotels. They have high resistance to heat (which can even reach up to 80 ° C of continuous use), while also supporting rigid temperatures.

In recent years, Aquatechnik’s polypropylene pipes have been further improved thanks to the use of a latest generation of raw material (PP-RCT) and the addition of an additives package called WOR (White Oxidation Resistance), with the dual function of improving performance at high temperatures and significantly slowing down the plastic materials oxidation process, due to the aggressive effect of substances that can be dissolved in the conveyed water.

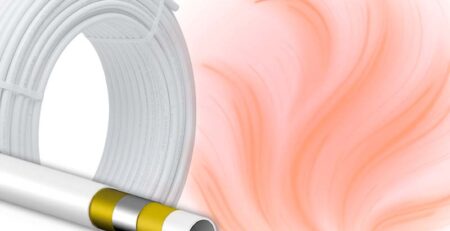

Below, the main characteristics of the multi-layer fiber-reinforced pipes (with internal layer in PP-RCT and WOR):

- improved resistance to oxidation

- reduced wall thicknesses with increased flow rate

- high resistance to pressure

- increase in operating temperatures

- significant reduction in thermal expansion.

Furthermore, the material used is 100% recyclable, with an LCA cycle of the product with low environmental impact.

The best pipes for drinking water

The wide use of polymeric materials for plumbing systems derives from its safety to transport fluids intended for human consumption. However, it is essential to use piping systems made of excellent quality material and conform to standards for the transport of drinking water.

Comparing other materials, for example, CPVC releases monomers into the water in the form of vinyl chloride, with negative effects on health. In this case, it is necessary to carry out specific compatibility assessments for potable use, which is unnecessary for polypropylene pipes.

In fact, Aquatechnik polypropylene pipes and fittings do not react with most of the chemicals that may be commonly present in water and maintain their characteristic.

The processing of materials can also affect the release of substances in the transported liquids: the joints between PVC pipes and fittings generally require the use of solvent-based sealers. In the fusio-technik system, the junction between the parts it’s made by hot fusion, which transforms the pipe and the fitting into a single piece of polypropylene, with no use of chemicals.

The certified safety of Aquatechnik polypropylene pipes

The Fusio-technik range stands out for its safety and reliability in the transport of drinking water (with the exception of the Rain-water and Fires systems dedicated to particular uses) and for the absolute compliance with the regulations governing its conveyance. The certifications obtained, such as the ICC-ES PMG Product Certificate for the North American market and DVGW – CSTB and IIP for the European market, confirm our commitment to safety in everyday applications such as plumbing systems for drinking water and for hydronic heating / cooling systems.

If you have any specific questions about the quality of Aquatechnik PP-R piping systems, please do not hesitate to contact our team of experts.