Differences between multilayer and polypropylene pipes: which one to choose for an hydraulic system

The choice of the right pipe type is fundamental for a correctly functioning and long lasting sanitary or heating system. The basic material of the used products determines the technical characteristics of the systems such as lifespan, operational conditions, flow and other particular elements fundamental for the functioning of the system.

In the history of hydraulics, we find traces of usage of various materials depending on availability in that geographical area, on the plasticity and on possibility of modelling. There have been found, as a matter of fact, remains of pipes made of clay, wood, bamboo, but also lead, cast iron, cement and finally nowadays we use synthetic materials. PVC, patented in 1913, found widespread use around the 30s and 40s and it is still one of the most used materials for sewers systems. At the same time, metal pipes such as steel and copper, used in distribution system to this day, continue to be the protagonists in the hydraulic implants world. However, beginning in the 80s, polymeric materials, such as pipes made of PP-R and multilayer pipes have gradually gained ground, thanks to their multiple advantages, among them a long lifespan, high resistance to degradation and formations of deposits and limestone.

Pipes made of polypropylene

A pipe made of PP-R is realised with polymer polypropylene-random. It is a simple material and chemically stable that does not contain toxic chemical substances and does not react with its nearby environme

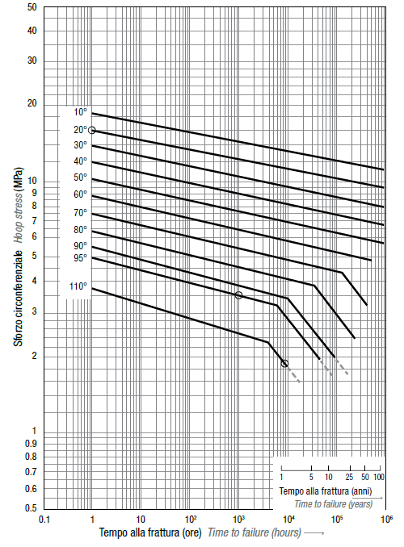

nt, nor with water. “R” in PP-R references to the presence of ethylene molecules that grant good rigidity, while still having decent flexibility, creating a resistant material that can still bend to facilitate its installation and deform enough to absorb impacts and avoid permanent deformations. The most advanced material is PP-R 80, where “80” represents the regression curve according to ISO 9080 tanking value MRS=8 MPa for the 20°C curve over a span of 50 years.

The polypropylene Random 80 Super version (MRS=10 MPa) by Aquatechnik, used for the fusio-technik system, grants improved performances that allow better operational conditions with equal pipe thickness: tests performed in compliance with EN/ISO 15874 confirmed that pipes with thickness SDR 7,4 (PN16) realised with PP-R 80 Super perform similarly to pipes with SDR 6 thickness (PN20) realised with PP-R 80 in conditions required by the aforementioned normative.

Recapping the advantages of PP-R for hydro sanitary applications, we can outline how chemically inert and hydrophobic it is, making it perfectly suited to convey potable water. Resistant to pressure and high temperatures up to 95°C, has an expected lifespan of at least 50 years in defined temperature and pressure conditions. Joints between pipes or between a pipe and a fitting is made with polyfusion, avoiding welding with open flames and/or glues, creating a single piece (monolithic structure), stable and resistant.

To contain the value of linear thermal dilatation, Aquatechnik has, in recent years, realised a range of multilayer pipes with a central layer charged with glass fibre: these special pipes reduce the value of thermal dilatation by 70% compared to monolayer pipes. Recently, the base material that makes up the inner layer of the pipe that touches the conveyed fluid, has been improved further by adding an additive (White Oxidation Resistance) and employing the latest generation of polypropylene type PP-RCT that significantly slows down the oxidation of the material and increases the resistance to high temperatures: they are the fiber reinforced pipes made of PP-RCT WOR.

Multilayer pipes

The multilayer pipe is made of at least three layers. The central layer made of aluminium allows the pipe to maintain its shape when it is bent or expanded to form the ”flaring”. The inner and external layers made of PE-X for its nature do not manifest the phenomenon of corrosion, typical of metallic materials. This guarantees that the pipe satisfies the strictest requirements for potable water systems. Consequently, multilayer pipes possess both the advantages of polymeric and metal pipes. The PE-Xb crosslink of multi-calor pipes of the external layer protects mechanically, chemically and electrically the aluminium layer under it, and the inner layer features a very low roughness reducing pressure drops.

The multilayer system multi-calor offers advantages of durability, with an expected lifespan of at least 50 years at constant use with pressures of around 10 bar and temperature peaks of 95°C: it has excellent resistance to abrasion and corrosion, clearly superior to metallic materials. The simplification of installation is evident thanks to its lightness and therefore transportability of the material, since it weights ¼ compared to copper and ⅕ compared to steel.

Multilayer vs polypropylene: which pipe to choose

Considering the effort of Aquatechnik to improve both solutions with big modifications and better performances, the choice between polypropylene and multilayer pipes for the realisation of systems for distribution of sanitary and potable water should be made according to the specific requirements of the project.

It should be considered:

- The diameter range needed: the fusio-technik system offers up to 630 mm, making it suited for projects where the flow expected is very high. The multi-calor system goes up to 90 mm with pipes in rolls only up to a diameter of 32 mm;

- The specific features of the building, from climate to type of structure to evaluate the best material considering resistance to humidity, cold or heat and the design of the system for a correct flow of water and its disposal;

- Environmental peculiarities such as the necessity of working at a high altitude, impossibility of using open flames or warm objects, limitations in freedom of movement or space;

- Costs, evaluate the choice of material considering manpower and time of installation in order to choose the less costly option.

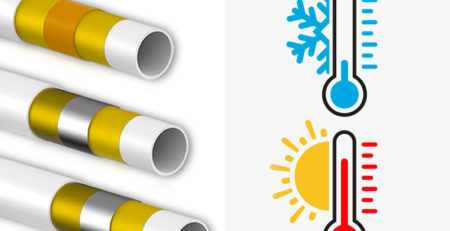

Regarding resistance, pipes in polypropylene have better performances, especially at high temperatures and against chemical substances. The WOR technology of Aquatechnik, as a matter of fact, is particularly suited for systems that reach high temperatures even for chemical treatments for disinfection of water and are up to 40 times more resistant compared to a traditional PP-R to oxidant agents such as free chlorine, chloramine and other chemical substances. The Aquatechnik multilayer pipes are as much resistant to high temperatures and the polymeric nature of the materials utilised guarantees a total absence of corrosive phenomenon typical of metals. They are also equally resistant to the main chemical substances to allow the multilayer pipes to be used in various applications.

Among the factors to consider there is the phenomenon of thermal dilatation, generally superior for all synthetic materials compared to metal.

However, multi-calor and multi-eco pipes behave similarly. The linear thermal dilatation coefficient a=mm/mk of multilayer pipes is 0,026, while that of galvanised steel is 0,012 and that of copper is 0,017. Normal polypropylene has a coefficient of 0,50 while faser fibre reinforced multilayer 0,035.

Lightness of the material is fundamental for installation, to make transportation and movements on the building site easier. Both polypropylene and multilayer pipes feature reduced weight.

Installation of a safety multilayer system can be considered easier and faster than the one with polypropylene pipes, which is nonetheless simplified by polyfusion (at variable temperatures from 210 to 260°C) compared to welding techniques of metal pipes (welding temperatures superior to 1000°C). Measurements on the field have proved the undeniable advantage of faser FIBER-T compared to threaded galvanised steel: with a basically equal cost, installation time with PP-RCT WOR is basically halved, from 7 hours and 50 minutes to 3 hours and 30 minutes to realise a riser column for warm and cold water for a 5-floor building. This difference is mainly due to little equipment required and easiness of jointing.

In Japan, a mock-up study commissioned by Takasago Thermal Engineering, compared two installations of the same plant utilising safety fittings with multi-calor pipes compared to steel, on a structure with 100 m2 ceiling with the function of supporting 10 air conditioning units. The test resulted in an installation time of 4 days for Safety and 7,5 days for steel.

Regarding operational costs, especially for the distribution of warm water, thermal conductivity is considered: λ equal to 0,22 W/mK for monolayer pipes made of PP-R Super, 0,19 for multi-layered pipes and 0,42-0,52 depending on the diameter for multilayer pipes much less than that made of copper. PP-RCT WOR pipes are therefore a guarantee of reduction of heat dispersion and consequently of energy saving.

Polypropylene pipes and multilayer pipes for any application

The advantages of polymeric materials, for multilayer or polypropylene pipes, are not limited to performance and installation, but also regarding the environment and safety. Both are non-toxic and suited for conveying potable fluids (with the exception of the multilayer POLIPERT version, polypropylene fibre reinforced FIRES version and monolayer RAIN-WATER) and eco-friendly solutions.

PP-RCT WOR and multilayer pipes by Aquatechnik are recyclable and have a low environment impact LCA. What is left to do is evaluate the details of the application of our solutions for the realisation of a state of art hydro sanitary system. It is moreover possible to use the BIM libraries to simulate the functioning of systems with our products.