The new heating power station for the Retirement Home “Madre Teresa Michel”

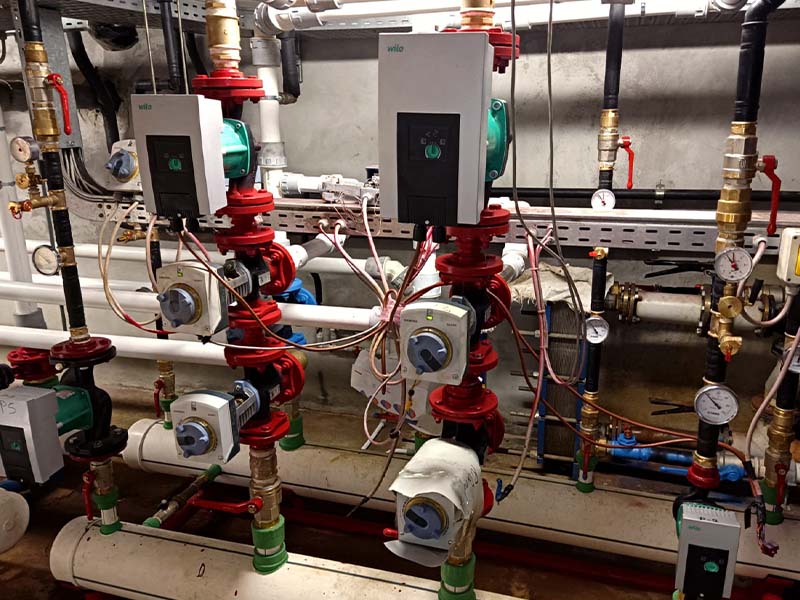

A masterful example of integration between Aquatechnik systems realized by the installer Ponte Sergio from Spinetta Marengo and the supply of Termosanitaria S.r.l. from San Michele.

The project was carried out in the province of Alessandria, at the Retirement Home “Madre Teresa Michel”, a structure from the early decades of the 1900s that has been expanded and renovated several times to the present day, always preserving its social function.

The aim of the project: a new heating power station

The aim of the rebuilding project was to renovate the heating power station: a challenge, but also an opportunity to improve the guests’ quality life and reduce operating costs.

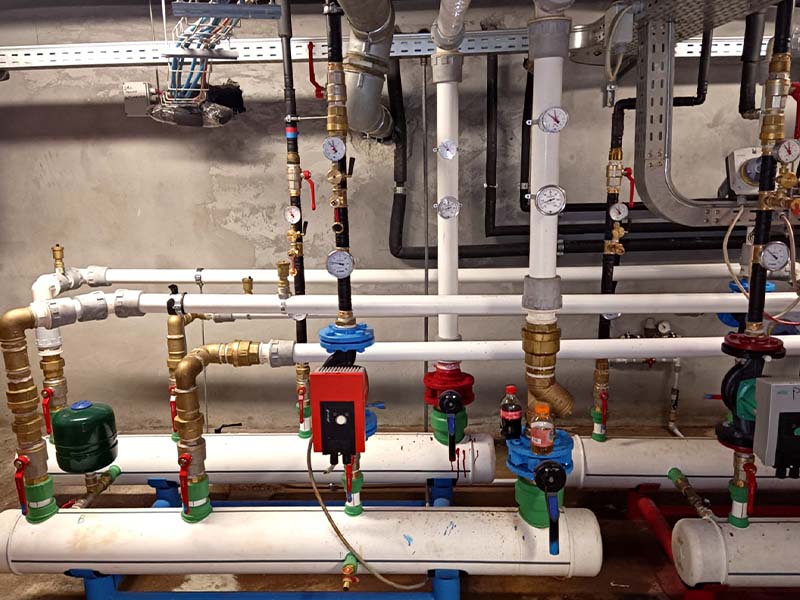

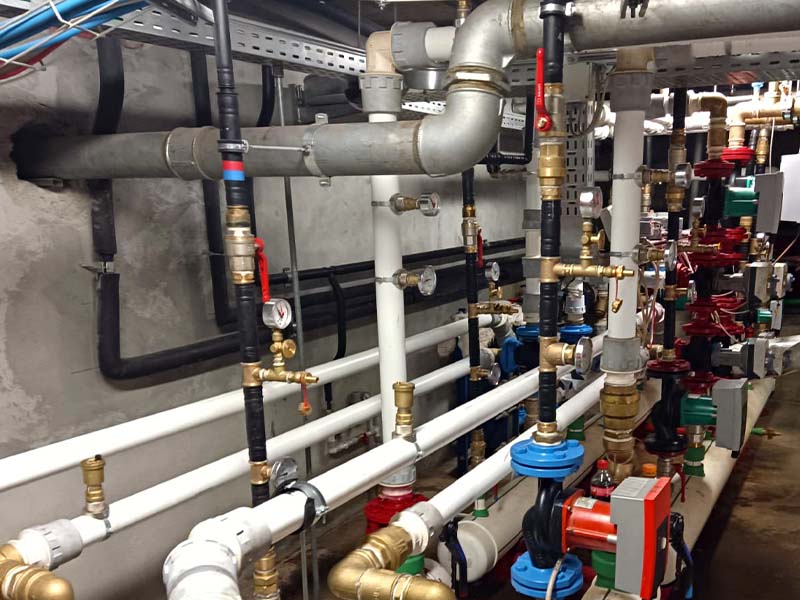

The integration of Aquatechnik multilayer and fiber-reinforced systems

The new heating power plant is the result of the integration between Fusio-technik and Safety systems: central manifolds made of faser FIBER-COND pipes with secondary branches in multi-calor piping.

The integration between multilayer systems with related Safety fittings and fiber-reinforced PP-RCT piping represents an innovative and reliable choice for the realization of plant engineering solutions. A winning combination, which allows to realize customized power stations.

The Aquatechnik Multilayer Pipe

Multi-calor multilayer pipes are made of an inner and outer layer of cross-linked polyethylene (PE-Xb) and an intermediate layer of aluminum, which provide excellent mechanical and thermal resistance, as well as essential lightness and flexibility during installation. In particular, PE-X is a polymeric material that undergoes cross-linking treatment, a process that increases its stiffness and resistance to thermal and chemical stress, making it suitable for high-pressure and high-temperature plumbing systems.

Fittings for multilayer pipes: Safety

Aquatechnik’s Safety fittings, on the other hand, are the key element in ensuring easy and safe installation. Thanks to its special geometric and patented jointing system (flaring), the system guarantees total flow while drastically reducing pressure, for significant economic savings. In addition, the Safety system, decreases processing waste, thanks to the possibility of recovering fittings.

W.O.R. (White Oxidation Resistance) fiber-reinforced piping technology

Aquatechnik’s fiber-reinforced pipes are the evolution of the single-layer polypropylene pipe. They feature a three-layer structure that gives them superior performance for any application, optimizing their resistance to oxidizing agents as well as high temperatures and pressures. The PP-RCT inner surface is additivated with last generation antioxidants to effectively stabilize the polymeric material, while the outer layer, PP-R 80 Super, and the middle layer, PP-RF, help reduce thermal expansion and impart ductility.

Customized thermal power plant: the advantages of polymeric materials

The integrated thermal power plant, made of polymeric material piping and fittings, is a particularly efficient solution for thermal power prodution, providing high performance and durability. One of the main advantages of an integrated thermal power plant made of polymeric materials is the absence of corrosion.

These materials, in fact, do not suffer the action of oxidizing and chemical agents, guaranteeing more than 50 years of operation, along with a relevant increase in Safety thanks to the joints, which take place by polyfusion in case of Fusio-technik pipes, or flaring, in case of the Safety system. Another undeniable advantage lies in energy efficiency. Using a polypropylene manifold, in fact, contributes to increase energy savings due to less heat loss.

Comparison with steel makes the advantage clear: the thermal conductivity of polypropylene is λ = 0.24 W/mK against λ of 52 W/mK for steel.

Finally, an Aquatechnik integrated thermal power plant is highly customizable and can be designed by building parts or manifolds tailored to each customer’s specific needs.

Because of its flexibility, it can be used in a wide range of applications, while its compatibility with other system elements allows for highly efficient plumbing systems that can respond to various requirements.

The integrated solution for every application: the wide Aquatechnik range

We are able to design and manufacture the widest range of high-quality integrated products for plant engineering to facilitate development and installation work. Transitions, reductions, couplings, flanges, tees and shut-off systems make it easy to integrate Aquatechnik piping with other systems. We are the ideal partner for professionals who want to meet the current challenges of installations in the residential, tertiary, industrial, historical and commercial sectors.