The installation of a district heating implant with Iso-technik in Padova

The Savonarola district in Padova owes its notoriety to the historic deeds of the family it takes its name from, of which to this day it is possible to admire the marks of an ancient beauty that remains in symbolic buildings, such as Porta Savonarola. It is in this context that we propose to you another project completed with Aquatechnik products.

The District Heating project in Padova

The project required the substitution of metal lines of heating that showed an evident state of deterioration caused by corrosion, serving 130 apartments.

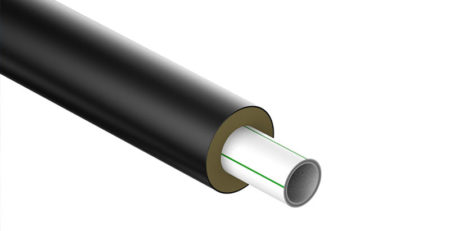

The plant was installed with the ISO FIBER COND system, with linear pipes with diameters ranging from 40 mm to 250 mm and delivery and return lines originating from a single central heating plant, long about 1.300 m. The manifold, from which the faser ISO FIBER-COND pipes start, was designed and produced custom-made with a diameter of 250 mm: it was placed underground in proximity of the central heating plant. From here, pipes are placed in digging and reach additional Fusio-technik manifolds, placed in special smaller wells, outside several apartment blocks.

The supply of materials was managed by Cambielli Pianiga, while P.A.F. Impianti managed the installation. The aforementioned company, which is specialized in metal and steel plants, welcomed this challenge with enthusiasm, declaring themselves very satisfied with the reliability of the system, the safety of the concealed joint and the unassailability to corrosive phenomena. A project truly prestigious and of the highest professionalism.

The benefits of District Heating

As it is known, district heating requires a single source of heating in order to provide to the heating requirements of several number of residential, commercial or multifunctional buildings. The central heating plant can use many different sources of heating, like fossil fuels (for example gas cogeneration) or renewable energy, such as heat pumps. Hot water travels through a network of underground isolated pipes to each building, to provide heating and hot water, allowing, moreover, separate control of the temperature in each building. Cold water then returns to the central heating plant in order to be heated up and be put back into circulation.

The advantages in terms of reduction of CO2 emissions are clear from the functioning, expecially when the source of energy is renewable.

District Heating can be used also in areas where a specific source of energy is not available, for example a lack of gas. The source of energy can be chosen for a project depending on the convenience, both in economic and efficiency terms. Moreover, the HIU (Heat Interface Unit) allows to spread and measure the heat created, replacing boilers in each building, with a not neglectable saving in maintenance, since, without the direct usage of fuel, both deposits and danger of malfunctions are eliminated.

In Italy, district heating is spreading more, and more also thanks to financial benefits and growing importance of safeguarding the environment. Furthermore, also the efficiency and therefore the energy saving is fundamental. However, in order to exploit all advantages of district heating it is indispensable to use the most performing solutions.

The ease of installation of pre isolate faser ISO FIBER-COND pipes

The ISO FIBER-COND system, in SDR 11 is particularly indicated to install heating plants for high temperatures, and therefore it proved itself to be most suited for the district heating project in Padova. The low loss of energy is, as a matter of fact, guaranteed by the low values of thermal transmittance and thermal conductivity, thanks also to isolation in PUR and sheath in PE-HD.

Several advantages of the Iso-technik system are linked to the specific weight of the material that makes it an effective system due to the ease of installation:

– dedicated equipment guarantees safe and fast welding. Joints can be made with hot-melt sealing for diameters 32-125 mm or butt welding from 160 mm to 315 mm;

– reduced weight compared to metal pipes, which facilitates the maneuverability and makes crane hoists superfluous on site;

– facilitated pipe casing removal for installation;

– assembly also outside the trench, useful expecially when the excavation is unusable;

– great capability to self-compensate for dilatation, in the absence directional change. Therefore, it is not required to predict interventions that would increase the cost of installation;

– assembly in “pre-tention”, namely the preheating the lines at 50% of the maximum temperature expected in the project.

Efficient and innovative solutions: this is Aquatechnik

Aquatechnik offers solutions for any specific request. Among these, there are also custom-made manifolds, like the one employed in this project. Being able to use custom-made pieces allows greater speed in the worksite, cost reduction of special equipment, more specific answers to any design requirement. Our team assists customers from the production request, making the designer’s job easier in any phase: contact our sales network in order to find an innovative answer to your needs.