Multilayer press fittings and compression fittings: the differences

When we consider hydrothermal sanitary systems, we can find many possible choices: we can choose between plenty of brands, but what in the end distinguishes a system are operational capabilities and energetic advantages. For this reason, it is important to reach the perfect compromise between quality of the product and performance of the pipe/fitting joint technique chosen.

Why choose multilayer pipes for hydrothermal sanitary systems

Multilayer pipes by Aquatechnik are made with several layers that complement each other: the central layer made of aluminium allows pipes to keep its shape when it is bent and functions as a barrier to oxygen. The inner layer made of PE-X guarantees resistance, makes the pipe compliant to the most strict requirements for potable water and guarantees the conservation of organoleptic features of water. The external layer, made of PE-X for multi-calor and of PE-HD for multi-eco, guarantees greater resistance to corrosion, compared to their metal counterparts.

The main points of strength of multilayer are lightness, flexibility and resistance to corrosion.

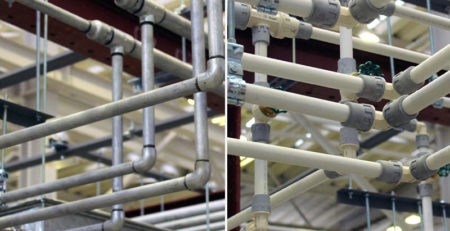

The reduced weight compared to metal pipes allows for an easy transportation on the working site, while flexibility represents an important advantage during installation, since it allows to keep the shape of the pipe and reduce the number of fittings needed.

The true difference is the resistance to corrosion, which allows to utilise the multilayer pipe by Aquatechnik in the most varied sectors, in the industrial one as well, guaranteeing a longer lifespan compared to metal. Multi-calor, for example, has a lifespan of at least 50 years at constant pressures of 10 bar and temperatures of 70°C. Among the other advantages of multilayer there are insulating properties and less pressure drops compared to metal pipes thanks to less roughness of the internal surface.

The winning combination: multilayer pipes and fittings

The choice of the most suited pipe for a system goes hand in hand with the choice of fittings. Among the different factors to consider, we must evaluate the compatibility of the materials with the purpose of the system and temperature and pressure that are expected. For multilayer pipes the pipe-fitting joint must not have weak points and must be categorically safe: for this reason, it is useful to know the types of fittings for multilayer pipes in order to make the right adjustments. On the market are available press fittings, compression fittings and total flow fittings. Let’s see the benefits and disadvantages of these technologies, in order to find the optimal solution.

Press fittings for multilayer

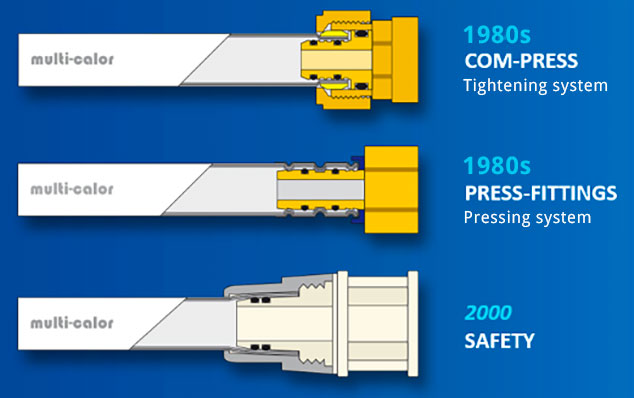

Press fittings are a high-performance solution for joints between pipes. Since their inception, at the end of the 50s, their popularity has been fundamental for the success of many projects. Since it is not necessary to weld, and therefore there is no need to generate heat, it a very clean and fast jointing method that is performed through compression. The joint is obtained by inserting a fitting inside a pipe after having calibrated the latter. Fitting and pipe are jointed with an electromechanical pressing machine. Pressing, compressing and bending the compass, anchors the fitting on the pipe permanently, realising the mechanical seal, while O-Ring guarantees hydraulic seal. For plumbers, HVAC professionals, designers and companies, press fittings are a great solution for at least three main reasons:

- Time and money saving. Compared to welding with metallic materials, press fittings allow a fast and simple joint to learn. Press fittings can make an installation job up to three times faster than with welding. Authorisations are not necessary unlike welding with flame, dud to its absence. This increases the safety of the working site and workers as well.

- Sturdiness and resistance to hits and violent impacts. If the pipe is correctly prepared according to the pressing system manufacturer’s instructions, the joint is similarly strong as welding. Human mistake can however incur when many pieces are worked on and a step is skipped.

- Flexibility for repairs as well. Press-fitting allows maintenance operations to be fast and easy. Joints can be made even if the system is still wet, avoiding delays.

Aquatechnik offers two types of press-fittings to satisfy this market demand:

- press-fitting metal, press fittings in brass with o-ring protection, available from a diameter of 16 to 63 mm, 18 mm excluded.

- Universal, a press fitting entirely made of polymeric material with an o-ring protection, available with a diameter from 16 to 32 mm, 18 mm excluded. Indispensable when the project requires the fluid to not be in contact with metals. Jointing is made by pressing as well.

Compatible cones of multilayer multi-eco and multi-calor pipes, guarantee perfectly hermetical joints and short installation time.

Compression fittings for multilayer pipes

Initially classified as a light solution for domestic installations, today compression fittings are used in a vast range of projects. These fittings proved to have reliable joints, but current regulations do not allow installing them inside walls. Compression fittings work with three main components: one piece that holds the pipe, one or more o-rings that create an hermetic sealing and an holding mechanism that keeps everything together. Like press fittings, they do not require flames. Their benefits are even more specific.

- Reduction in installation times. Compression technology was designed to optimise time and make the installers’ job easier in several points.

- Limited equipment needed. Unlike press fittings, compression fittings do not require extra equipment for installation. Once cutting, measuring and flaring of the pipes has been done, the actual jointing requires few seconds. They do not require pressing machines, nor great strength when installing the fitting.

- Easy disassemble. Another key advantage is that the fitting can be disassembled easily in case of a mistake during installation or removal, an operation almost always impossible with press fittings or traditional methods.

- Perfect for working in cramped spaces. Compression fittings are particularly fit for work in small areas. When space is limited, the risk is that the joint is not safely installed if the installer is not able to access the pipes properly to use the crimping tool, factors that could greatly influence the quality of the joint.

The Evolution of multilayer fittings: the safety system

The total flowing fittings by Aquatechink represent the evolution of jointing systems for multilayer pipes.

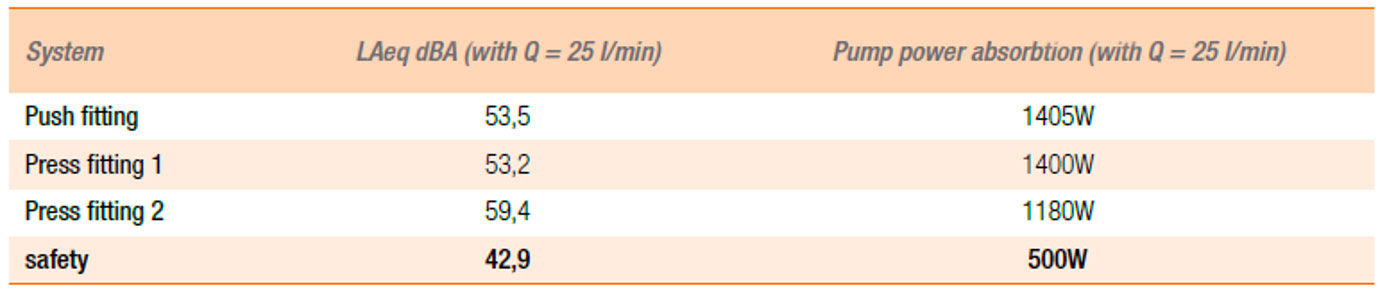

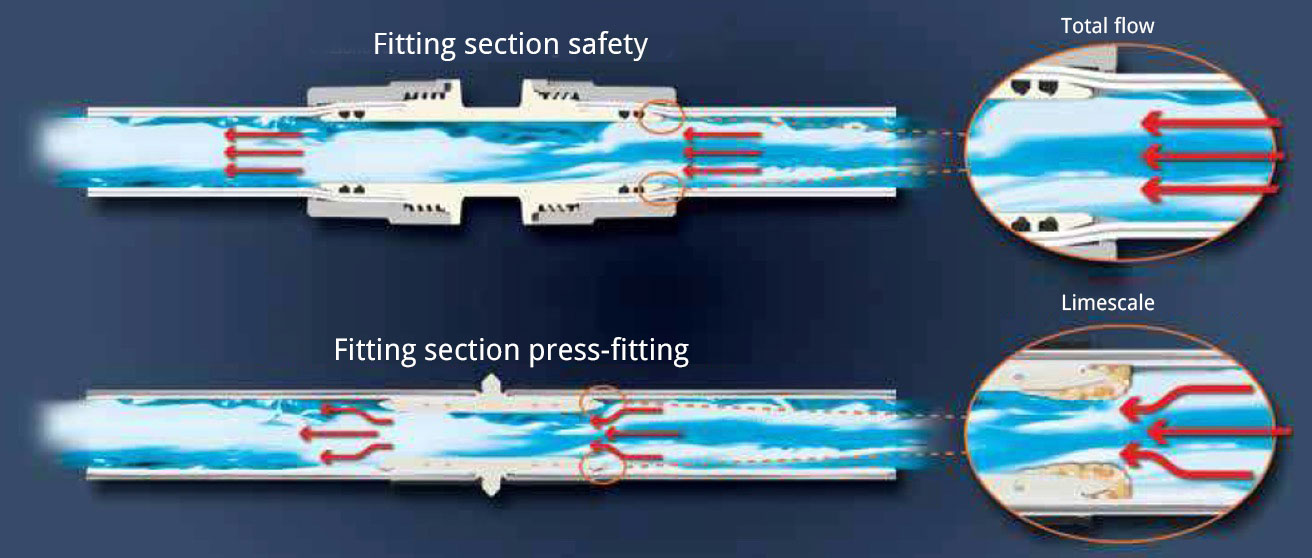

With the objective of solving the disadvantages of traditional joints, particularly the flow reduction at the joint between pipe and fitting and the weakness and the aforementioned, safety was born, a system that guarantees double the sealing, both hydraulic and mechanic and a significant reduction in pressure drops, attrition and noise. In traditional fittings for multilayer pipes (press and compression fittings), the piece that is inserted in the pipe greatly reduces the flow and consequently pressure. This contributes to the formations of deposits with great consequences for the functioning of the system. The most direct consequence is the higher workload required for the pump to make the system work, and therefore energy consumption increases. The safety system, other than granting an increase of flow of around 40% compared to other joint systems with multilayer pipes, guarantees also an average energy saving of 60%.

This result is achieved by the enlargement of pipes end (flaring) and the particular geometry of the fitting that allows to fit it on the pipe easily, fast and in total safety.

The fitting is installed on the pipe through a cap with an anti-rotation system to guarantee fixing. The recovery of the fitting is therefore simple and fast. Among the other advantages of safety, there is a great resistance of corrotion, thanks to the synthetic material that is made of, guaranteeing a life span of at least 50 years.

A further advantage is the reduction of installation time. Differently from traditional methods, the safety system does not require the calibrating of the pipe. Comparing safety with a common press fitting, in an installation of a typical bathroom with a manifold, 23 fittings are needed with press fittings and 17 with safety and, most importantly, one hour and 56 minutes on average with press fittings and one hour and 8 minutes with a safety system to complete the installation.

Multilayer fittings for any joint with Aquatechnik

Aquatechnik offers therefore a total flow solution with advantages clearly superior to traditional systems especially in terms of energy efficiency. Our fittings, moreover, include a wide range of articles and special pieces up to 90 mm, that allow to reduce the space taken and decrease the cost of installation due to less material needed. Reductions, manifolds and tee make designing and installing easier, using specific equipment patented by Aquatechnik.

Discover how safety can be the viable alternative to traditional fittings to optimise joints with multilayer pipes.