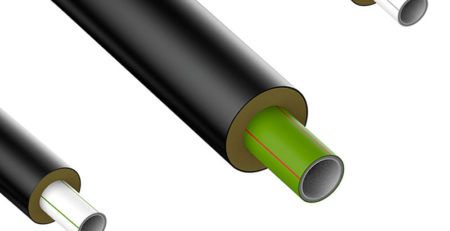

Performance comparison between the Safety-pol system with Multi-calor pipes and steel ones

A great mockup project realized in Japan by our exclusive Agent Toyox

The aim of the project was to evaluate the functional and constructive performance of the Safety-pol system with Multi-calor pipes compared to steel installations, which, to date, constitute the preferred systems in Japanese plant engineering.

Premise

In order to achieve objectivity, the same manufacturer worked with both systems, using a single construction design, consisting in the construction of a ceiling structure of 100 sq in width, with the function of supporting 10 units of air conditioners.

The manufacturer in charge, specialized in the installation of steel systems, at the time of implementation of the project was completely inexperienced with the laying techniques of the Safety system. For this purpose, he received a short training lasting about 1 hour.

Final results

– The construction of the steel structure had a duration of 7.5 days against the 4 of the Safety system: working times decreased by 47%!

– The manufacturer has defined the Safety junction system as extremely simple and practical.

– The processing (flaring) is standardized for each step, so the operators have easily learned the installation techniques to guarantee good quality in construction processes

-The difference in weight between the Multi-calor pipe and the steel one significantly simplified handling and moving on the construction in site, also reducing transport costs.

-The intrinsic features of resistance to corrosion of the plastics ensure a lifetime of at least 50 years, higher than that of steel

This ambitious project has shown many advantages that could create a real revolution in Japanese plant engineering. However, it is necessary to train designers and engineers, providing the appropriate tools to design with the Safety system and supporting technicians with specific documentation.

In order the Safety system to become the protagonist of this revolution, a capillary distribution network should be created, granting the availability of the product, and a change in the culture of savings must be promoted, because, if it is true that the Safety fittings has higher costs than the steel one, when the project is completed the savings are definitely unbeatable!