Aquatechnik innovation for the Iso-technik range

Aquatechnik has made innovation one of the strengths that distinguished it since the beginning. The continuous search of the best solutions for the plumbing and heating sector is essential to meet the needs of the market and installers. The quality of our products starts from the attention to our partners in a work of mutual collaboration. Not only words: the confirmation of our commitment is testified by the recent improvements made to the Iso-technik system.

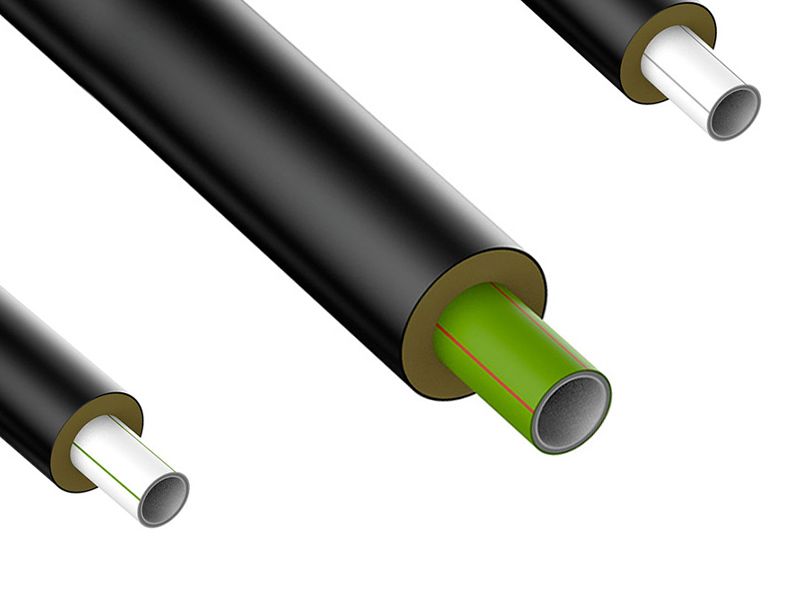

Pre-insulated pipes: the Iso-technik system

The Iso-technik system includes single pipes and pre-insulated fittings in PUR foam (stiff polyurethane) protected by a casing pipe made in PE-HD. Particularly suitable for remote energy distribution, the Iso-technik range consists of pipes:

- iso FIBER-T SD7.4, suitable for sanitary systems at high temperature;

- iso FIBER-COND SDR 11, ideal for sanitary systems at medium temperature and heating systems at high temperature;

- ISO FIBER-LIGHT SDR 17.6, for heating systems at medium temperatures and pressures and for sanitary systems at low temperatures.

The internal service pipes and fittings are made with the most advanced materials, of European production: PP-R Super 80 and PP-RCT WOR (White Oxidation Resistance), developed by Aquatechnik with special additives which ensure greater resistance to oxidizing agents.

Iso-technik is particularly suitable for the remote transfer of energy between thermal power stations for the production of heat, chillers, heat pumps, geothermal systems, thermal systems, etc. and the utilities involving networks of pre-insulated underground pipes.

The advantages of the Iso-technik system

Ease of installation and energy saving make it a very popular system.

The weight reduction, compared to metal pipes, facilitates agility on site, avoiding the use of cranes or hoists. The junction takes place through polyfusion or electro-fusion, with dedicated welding machines according to the diameter and needs. The casing of the pipe is manageable, and it is possible to assemble the line outside the trench, a particularly useful advantage in the event of adverse weather conditions that make the trench unusable. Finally, installation is facilitated by the significant self-compensation features of the Iso-technik system, so it will not be necessary to provide for corrective interventions such as omegas, loops and mechanical compensators that affect costs.

Greater energy savings with Iso-technik

Energy saving is essential to create a system with excellent performance, reduced construction costs and with low environmental impact.

The Iso-technik system, with pipes in PP-RCT WOR, guarantees reduced pressure losses thanks to an internal roughness of 0.007 mm, against 0.20 mm of steel pipes, thus generating low friction to facilitate the flow of the fluid. This is a feature that affects the operation of the pumps, which will be able to work at lower speeds, consequently consuming less energy. This advantage is also due to a high resistance to corrosive phenomena, significantly reducing limestone, sludge and rust deposits.

One of the most appreciated strengths of the Iso-technik system is the reduced loss of energy due to a very low thermal transmittance U value, starting from the λ value of the service pipe, 0.19 W/mK, against 52 W/mK of steel. The combination with the polyurethane foam composed of polyol and isocyanate, injected into the interspace between the service pipe and the external casing pipe (made in PE-HD), creates an insulation that makes the pipes extremely efficient in terms of energy containment.

Today, even more performing

The recent intervention on the insulation foam, carried out through a specific computerized equipment that controls in real time the stoichiometric dosage, the mixing of the two basic components (polyol and isocyanate) and the injection of the mixture has allowed to obtain even better results in terms of energy efficiency. The thermal conductivity of the PUR foam, with an initial λ equal to 0.0227, was brought to a value of λ equal to 0.0142 W/mK. Even the stabilized thermal conductivity improved, used for the design, which went from 0.027 to 0.023 W/mK.

The characteristics of the service pipe, the PUR foam and the external casing pipe allow to obtain very relevant performance advantages. For example, considering a system with a heat pump and with a basin from which to draw water to bring to the condensers, it is essential to have the lowest possible temperature difference in terms of dispersion in order not to nullify the efficiency advantages.

Innovation of the future, today

When innovation and research are fundamental values of a company’s philosophy, exceeding the set goals becomes a daily challenge. We are committed to pursuing our goals, ensuring quality, safety, efficiency and energy saving in compliance with environmental eco-sustainability.