The differences between PVC and polypropylene pipes

The polymer market is constantly evolving and is also suffering the effects of a generalized crisis due to the pandemic, which has reduced the supply of raw materials, with consequences on the entire production and sales cycle. In a context such as the one described, also considering the technological evolution of materials, it is essential to shed some light in order to choose the best system solutions. Let’s start with an important difference: PVC pipes and polypropylene pipes.

PVC pipes

PVC stands for polyvinyl chloride, a type of chlorine-based vinyl polymer material. There are different types of PVC pipes: single-layer and multi-layer.

These are pipes that have good mechanical characteristics, but heat resistance is limited to 60 ° C in the case of PVC-U. PVC pipes have a wide variety of applications: they are usually used for pressurized water supply systems, drainage, irrigation, rainwater collection. PVC pipes are also known to be durable and lightweight, which makes them especially popular.

Polypropylene pipes

Polypropylene is a polymeric material that also allows the creation of light and easy-to-transport pipes. Polypropylene pipes, like all those made of polymeric material, have a very smooth inner layer compared to other types of pipes (e.g. those made of steel), thus ensuring minimal friction and low pressure drops during transport and distribution of the conveyed fluids.

Used for plumbing and heating since the 1980s, PP-R pipes also offer good chemical resistance. Polypropylene pipes have high heat resistance and good performance even at low temperatures. For this reason, also for the non-toxicity of the material, PP-R pipes are ideal for the transport of drinking water. The polypropylene products are also characterized by the ease of installation that takes place by polyfusion, a simple and rapid process, which makes the joints more reliable.

PVC and polypropylene piping: a direct comparison

By analyzing some characteristics of polypropylene and PVC pipes, the differences can be better understood.

- Raw material

Polypropylene has the following peculiarities: resistance to high temperatures (peak up to 110 ° C), lightness (density less than 1g /cm³), possibility of joining by thermofusion, high chemical resistance.

PVC has the following characteristics: reduced resistance to high temperatures (max. 60 ° C), a much higher density, the need to check the release of monomer vinyl chloride and the impossibility of joining by thermofusion. Superior in terms of flame resistance and economy.

The respective peculiarities of the raw materials are therefore reflected in the characteristics of the products made with them.

- Costs

The price of the pipes varies in relation to the type, thickness and diameters. Regardless of the cost of the pipeline itself, the overall costs must instead be considered depending on the type of application, labor and duration of the system.

- Installation

The installation of polypropylene pipes is very convenient thanks, as seen, to polyfusion welding, without the use of chemicals. All these factors are reflected in a low environmental impact and limited costs.

Performance of pipes in polymeric material

Compared to traditional metal piping systems, polymeric materials do not show phenomenon of corrosion.

The thermal conductivity compared to metallic materials is very low, resulting in better energy efficiency of the systems and lower insulation costs.

Different applications

PVC pipes are widely used in various applications, starting from the distribution of water, to the collection of wastewater and rainwater. Due to their poor resistance to high temperatures, they have limitations in thermal systems.

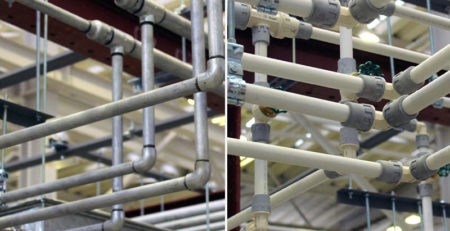

Polypropylene has a wide range of applications, including: hot and cold water sanitary systems, heating systems, transport of liquid for human consumption, compressed air and transport of aggressive liquid substances (for which a prior evaluation of compatibility it’s made).

The evolution of Polypropylene

The continuous search for quality and innovation, that has always distinguished Aquatechnik, has led to perfecting the basic materials used to produce more performing pipes and fittings.

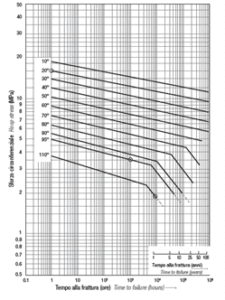

The fusio-technik system, born in the early 1980s, used Polypropylene Random 80, PP-R 80

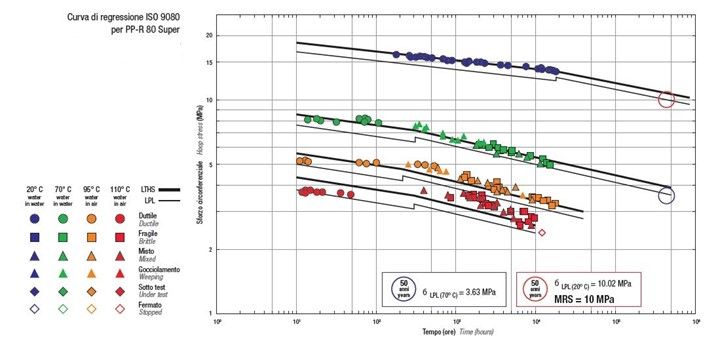

ISO 9080 regression curve of PP-R 80

In the 90s a second innovation was introduced: the material of the fusio-technik range in PP-R 80 is replaced by Polypropylene Random 80 Super, which gives better performance.

The advantages of PP-R 80 Super concern the reduction in thickness, with the same performance, which results in making the installation easier in various areas.

The creation of fiber-reinforced piping systems was a decisive progress, where in the central layer a special layer with fibers is coextruded: with this technology, the linear thermal expansion of the pipes has been reduced by 70% compared to single-layer pipes, which has allowed more and more technologically important applications.

Thereafter, a latest generation of raw material (PP-RCT) with improved thermo-mechanical characteristics was introduced. Thanks to the addition of an additives package called WOR (White Oxidation Resistance), performance at high temperatures has been further improved and the resistance to oxidative attack, due to the effect of substances that can be dissolved in water (such as purification agents), has been increased.

Aquatechnik’s fusio-technik range

Characterized by the elevated resistance to high temperatures and pressure during operation, the fusio-technik range offers suitable solutions for the most diverse needs of installers.

Single-layer pipes:

Fusio-technik rain-water SDR 11 (specific for recycled and recovered water – not suitable for potable use)

Multi-layer fiber-reinforced pipes (with internal layer in PP-RCT / WOR)

UVRES SDR 7.4-11 (with additives in the outer layer that ensure high resistance and durability to direct exposure to sunlight)

Aquatechnik solutions for plumbing and heating systems are innumerable and each one responds to specific need, with all the advantages of the basic material, polypropylene, enhanced by the innovation that has guided our company philosophy since its foundation. Contact us for more information.