Fittings for Multilayer Pipe: What is flaring

Flaring consists in the enlargement of the pipe heads in order to create a housing seat to accommodate the fitting or another pipe.

This joining technique, already popular for pipes of metallic origin such as copper, has been studied, perfected and adapted to be proposed in a new form as a connection system between PE-X/Al/PE-X multilayer pipes and the patented Safety fittings.

The Safety-plus fittings

Twenty years ago, the Safety system made its appearance on the Italian thermo-hydraulic landscape: an innovative and revolutionary pipe/fitting joint system that is the result of an all-Italian intelligence. Over the years, passing through countless and very strict tests, the Safety system has obtained the most important Italian and foreign certifications, establishing itself as an Italian excellence in the world. Safety is the full-bored fitting range patented by Aquatechnik, born from the aim of removing the disadvantages of traditional multilayer fittings that reduce the passage section and therefore generate significant pressure drops.

Safety-plus is a complete range of fittings from Ø 14 to Ø 90 mm, made entirely of synthetic material, able to preserve the organoleptic characteristics of the conveyed fluids avoiding the contact with the metal parts.

The fitting body is made of PPS (Polyphenylene Sulfide) a high-performance material with high chemical resistance, with PA-M (Modified Polyamide) caps and EPDM O-rings (Ethylene Propylene Diene Peroxide Shore A70).

Aquatechnik multilayer fittings are suitable for the construction of thermal power station, sanitary water, heating and air conditioning distribution systems, supporting pillars, compressed air distribution, and industrial systems for transporting various kinds of liquids.

The advantages of Safety-plus flaring

Joints between Multi-calor or Multi-eco series pipes and Safety-plus fittings are unique in their kind because they do not occur by pressing or tightening, but through the conical junction concept.

The interaction between the profile of the hose holder and the geometry of the flare impose the specific deformation of the O-rings to guarantee the hydraulic tightness of the joint, while the cap ensures the mechanical seal, preventing any movement both in conceiled applications than free-laying. However, the fitting can be disassembled and recovered, avoiding processing waste.

In addition, only one device called Pipe Flaring Machine, supplied by Aquatechnik, is needed to connect the fittings to the multilayer pipes.

The advantages of flaring with the Safety system are:

- Speed: each processing cycle takes only a few seconds

- Increased flow rate and consequent energy savings

- reduction in friction and noise

- reduction in overall dimensions

- reduction in required equipment

- cost savings compared to the use of tees and reductions, thanks to special F/F figures.

How to performe flaring

The flaring process of Aquatechnik multilayer pipes involves the use of special equipment that operates inside the pipe, increasing its diameter.

The special equipment, also patented, has been specially designed to work the Aquatechnik’s multi-calor pipes, respecting the ratio between the thickness of the elements, in order to ensure the high quality of the joint, without compromising the physical and mechanical features of the pipe itself.

Aquatechnik provides installers with a complete range of equipment to perform pipe widening in a safe and calibrated way.

Aquatechnik flaring machine can be:

- manual or motorized with 18V battery power for working from 16 to 32 mm;

- motorized, with 18V battery power for working from 40 to 90 mm.

The working process is simple, fast and safe for all the proposed diameters and no countersinking or calibrations are needed before flaring.

The procedure for performing a flaring can be summarized as follows (always refer to the instruction manual enclosed with the Aquatechnik Pipe Flaring Machine):

- assemble the expansion kit according to the pipe diameter to be processed

- cut the pipe precisely at the predetermined point

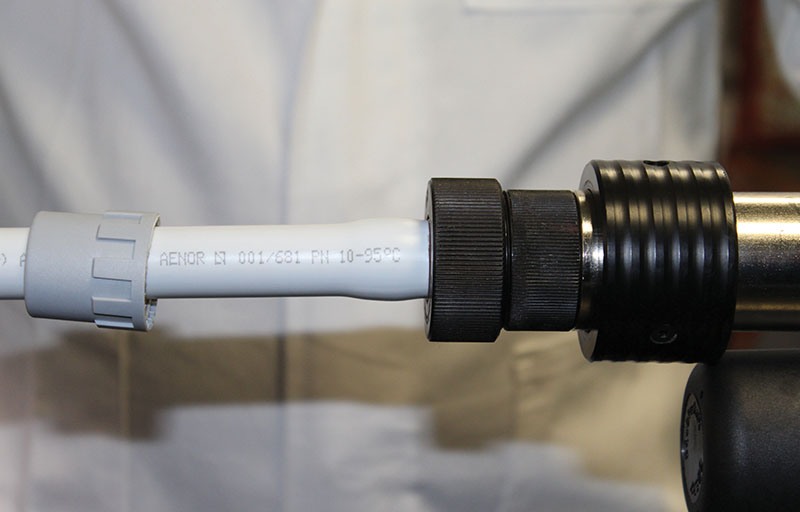

- insert the cap into the pipe

- insert the pipe onto the flaring machine head

- start the machine until the flaring is complete (the pipe will be automatically released)

- insert the fitting into the obtained flare by pushing up to the stop

- Screw the cap up to the anti-loosening safety notch using the appropriate spanner

All the steps to make a flaring